It's my first time programming a PLC, any help would be appreciated.

I'm using a proximity sensor to detect an object, followed by a solenoid to spray the object. There are two timers, one to delay the spray while the piece moves into position (if necessary) and a second that adjusts spray duration.

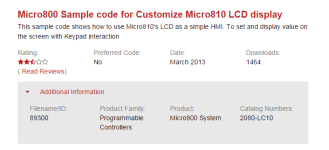

I'd like the user to be able to adjust the times from the LCD, but it shows "no variables" under the variable screen. I tried making them local and global, no success. I'm not sure what to do.

On a side note, I used the set and reset functions to keep the input "on" while the timers execute. It works, but maybe there's a better way?

Thanks

I'm using a proximity sensor to detect an object, followed by a solenoid to spray the object. There are two timers, one to delay the spray while the piece moves into position (if necessary) and a second that adjusts spray duration.

I'd like the user to be able to adjust the times from the LCD, but it shows "no variables" under the variable screen. I tried making them local and global, no success. I'm not sure what to do.

On a side note, I used the set and reset functions to keep the input "on" while the timers execute. It works, but maybe there's a better way?

Thanks