ronny_resistor

Member

Hello once again.... I am a Wiz with RSView32 and EZ automation. So along comes the salesman .....

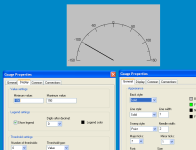

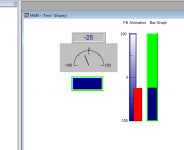

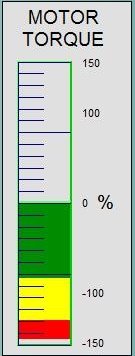

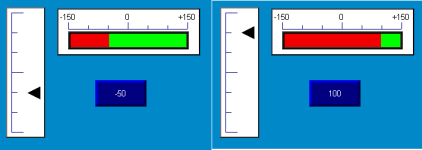

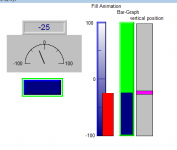

Factory Talk Me 8.00 Bar Graph / Gauges, Has no one on the Allen Bradley side ever used gauges that go both ways such as -150% to +150%. The Gauge works great from 0 -100% but I cannot find any instruction that EASILY insets the -100% such as the MOTOR TORQUE it goes both ways yet there is no Bar Graph and that cheapish looking Gauge should be buried in the back yard

If i am missing something please let me know as of now i do not know why i bought these expensive touchscreens and software

Factory Talk Me 8.00 Bar Graph / Gauges, Has no one on the Allen Bradley side ever used gauges that go both ways such as -150% to +150%. The Gauge works great from 0 -100% but I cannot find any instruction that EASILY insets the -100% such as the MOTOR TORQUE it goes both ways yet there is no Bar Graph and that cheapish looking Gauge should be buried in the back yard

If i am missing something please let me know as of now i do not know why i bought these expensive touchscreens and software