Hi,

We have a dosing system that uses the 224XP REL 02.01 CPU. It has a encoder input wired to input I0.1 and monitors the position and speed of the machine in order to trigger the dosing.

We have had some problems with it and I suspect there is an issue in the code as the few inputs it has seem ok.

The encoder has been replaced just in case and is ok.

Not sure why but the PLC info shows a minor fault with the following description....

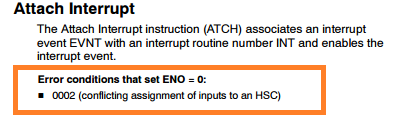

'Input interrupt to a point already assigned to an HSC'

It points to INTERRUPTS program at network 4

I don't know enough about siemens to understand why this has occurred. Can someone help me to understand this?

Thanks,

We have a dosing system that uses the 224XP REL 02.01 CPU. It has a encoder input wired to input I0.1 and monitors the position and speed of the machine in order to trigger the dosing.

We have had some problems with it and I suspect there is an issue in the code as the few inputs it has seem ok.

The encoder has been replaced just in case and is ok.

Not sure why but the PLC info shows a minor fault with the following description....

'Input interrupt to a point already assigned to an HSC'

It points to INTERRUPTS program at network 4

I don't know enough about siemens to understand why this has occurred. Can someone help me to understand this?

Thanks,