Dera bsee

Member

Hi everyone,

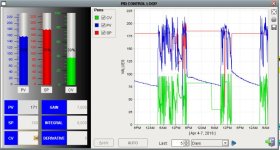

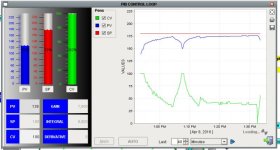

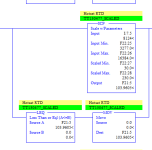

I'm having problems with the response time on my PID loop. I've tri.ed different tunnings but none have worked. In order to have my system running smoothly my engineering manager had to set the P (gain) at 700 and I (reset) at 800 which is baffling. Normal tunnnings are not working and even with that the response time isn't fast enough. The controller is a SLC 5/05 and the other PID loops in the processor have normal tunnings such as a gain of 8, reset of 1, and derivative of 1. Has this happened to anyone before? That control loop is all over the place and other norm tunning doesn't work. How should I approach this? I don't see why I would need such high parameters in order to get a desirable response time and even with such high gain and reset time, the response is not fast enough. Do you think there's a glitch in the controller or something with he hardware? What's your opinion?

I'm controlling temp

I'm having problems with the response time on my PID loop. I've tri.ed different tunnings but none have worked. In order to have my system running smoothly my engineering manager had to set the P (gain) at 700 and I (reset) at 800 which is baffling. Normal tunnnings are not working and even with that the response time isn't fast enough. The controller is a SLC 5/05 and the other PID loops in the processor have normal tunnings such as a gain of 8, reset of 1, and derivative of 1. Has this happened to anyone before? That control loop is all over the place and other norm tunning doesn't work. How should I approach this? I don't see why I would need such high parameters in order to get a desirable response time and even with such high gain and reset time, the response is not fast enough. Do you think there's a glitch in the controller or something with he hardware? What's your opinion?

I'm controlling temp