I have a temperature control loop that control a cooking kettle.

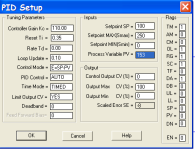

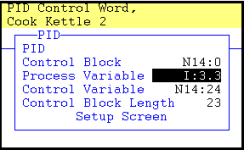

I bring the temperature in through a input card. I use a scaling instruction to see what degree F it is. For years I have the temperature 0-250 degrees moved into the process variable & it would read as the temperature F in the PID loop and it worked well.

Recently it stopped working. Even though the PV was being populated with the current temperature, it would not display in the PID loop.

I ended up sending the whole span from the input device. 16000 - 32767 to the Process Variable. Then it started display the temperature in the PID loop as a temperature between 0-250.

Dose anybody know why these numbers would change?

I am sure it something simple, It is magic to me right now.

Thanks,Scot

I bring the temperature in through a input card. I use a scaling instruction to see what degree F it is. For years I have the temperature 0-250 degrees moved into the process variable & it would read as the temperature F in the PID loop and it worked well.

Recently it stopped working. Even though the PV was being populated with the current temperature, it would not display in the PID loop.

I ended up sending the whole span from the input device. 16000 - 32767 to the Process Variable. Then it started display the temperature in the PID loop as a temperature between 0-250.

Dose anybody know why these numbers would change?

I am sure it something simple, It is magic to me right now.

Thanks,Scot