Hi all,

Just wondering if anyone has any ideas to easily detect a change in any of the elements of a UDT, other than brute force?

Looking at a recipe system, and I want to achieve the following:

- User selects recipe, and the recipe parameters are copied from a database into a local UDT which controls line parameters

- User wants to change one parameter just for now, but not actually edit the recipe

- User changes that one parameter. UDT is changed, but the change is not uploaded to the database

- PLC detects that there has been a change in one of the UDT elements and puts an alert onto the SCADA that they are currently running a modified recipe

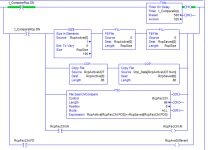

Any ideas? I was hoping it would be as simple as an EQU and a LastScan tag, but EQU doesn't work on UDT's. Brute force (checking every element individually) will be a pain because the UDT's are quite large, so I'm hoping for a more creative solution.

Thanks!

Just wondering if anyone has any ideas to easily detect a change in any of the elements of a UDT, other than brute force?

Looking at a recipe system, and I want to achieve the following:

- User selects recipe, and the recipe parameters are copied from a database into a local UDT which controls line parameters

- User wants to change one parameter just for now, but not actually edit the recipe

- User changes that one parameter. UDT is changed, but the change is not uploaded to the database

- PLC detects that there has been a change in one of the UDT elements and puts an alert onto the SCADA that they are currently running a modified recipe

Any ideas? I was hoping it would be as simple as an EQU and a LastScan tag, but EQU doesn't work on UDT's. Brute force (checking every element individually) will be a pain because the UDT's are quite large, so I'm hoping for a more creative solution.

Thanks!