rjyusmc2005

Member

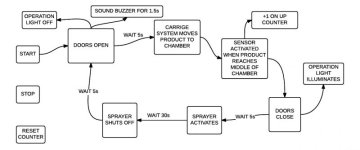

What am I doing wrong? This is a project for school and I thought I had it until I added the JMP/LBL instruction set to work as a loop. When I do that, it freezes once it gets there. I want this to cycle thorough start to finish from the time you press the start button (I:1/0) until the stop button (I:1/1) is pressed. I know it may not be the most efficient way to implement it, but it is functional, except for the loop. Any guidance or suggestions how I can fix the this to get it to properly loop would be greatly appreciated. Is there a better way to reset all the counters at once other than a reset command for each of them near the end of the program?

Oh, this is using LogixPro software.

Oh, this is using LogixPro software.