kitlegg

Member

Hello. I am brand new to PLC programming, as in I took a few introductory classes two weeks ago. I am trying to help a family member with a project he is working on. He is building a footbath for dairy cows. It is a bath that the cows walk through after being milked that has a chemical mixture that keeps their hooves from getting infected.

The PLC needs to fill up the footbath with the correct dosages of water and chemical. The barn runs 24/7, and there are three milking shifts every day, 8 hours each. The chemical treatment only happens during the 8:00 AM to 4:00 PM shift.

During the treatment shift, the PLC must fill the bath at 8:00 AM. It must then wash down the bath with clean water and refill every two hours. During the other two shifts, the PLC must continue to wash down the bath every two hours.

I have completed most of the program but cannot seem to cross the finish line. That is where you all come in!

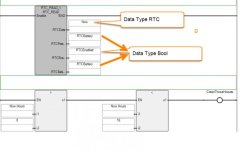

How do I program the treatment shift to start at 8:00 AM daily?

I am using an Allen-Bradley Micro820 and the Connected Components Workbench.

Thank you in advance for your help!

The PLC needs to fill up the footbath with the correct dosages of water and chemical. The barn runs 24/7, and there are three milking shifts every day, 8 hours each. The chemical treatment only happens during the 8:00 AM to 4:00 PM shift.

During the treatment shift, the PLC must fill the bath at 8:00 AM. It must then wash down the bath with clean water and refill every two hours. During the other two shifts, the PLC must continue to wash down the bath every two hours.

I have completed most of the program but cannot seem to cross the finish line. That is where you all come in!

How do I program the treatment shift to start at 8:00 AM daily?

I am using an Allen-Bradley Micro820 and the Connected Components Workbench.

Thank you in advance for your help!