Peter Nachtwey

Member

Oh No! Not that again!

I will start out sort of simple ( evil thoughts )

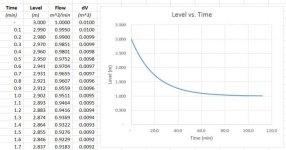

Suppose I have a tank that is 4 meters tall with a constant surface area of 1 square meter. There is a pump with a capacity to pump 1 cubic meters per minute and the pump is controlling the outflow. Assume the pump responds quickly so the pumps response time is 0. The motor speed and pump flow responds linearly to control signals between 0 and 100%.

There is no in flow......for now. ( evil laugh )

The set point is set for 1 meter and the level is now 2 meters. The control is a dirt simple proportional band where the pump stops at 1 meter and is on 100% at 3 meters.

If the level happens to be at 3 meters and no other fluid is added, how long will it take for the fluid level take to get to 1 meter. The control is still the same.

Get out your Excel spread sheets.

If you know the answer the PM me.

I will start out sort of simple ( evil thoughts )

Suppose I have a tank that is 4 meters tall with a constant surface area of 1 square meter. There is a pump with a capacity to pump 1 cubic meters per minute and the pump is controlling the outflow. Assume the pump responds quickly so the pumps response time is 0. The motor speed and pump flow responds linearly to control signals between 0 and 100%.

There is no in flow......for now. ( evil laugh )

The set point is set for 1 meter and the level is now 2 meters. The control is a dirt simple proportional band where the pump stops at 1 meter and is on 100% at 3 meters.

If the level happens to be at 3 meters and no other fluid is added, how long will it take for the fluid level take to get to 1 meter. The control is still the same.

Get out your Excel spread sheets.

If you know the answer the PM me.