Hey all, hope your day has been wonderful.

I’ve been asked by a local company to drive 10 hours to finish programming and tuning a machine they had built by another company in NY so they can run off, tear down and ship to MI. The machine works, but needs to be finished.

Their programmer left for some reason, but the local company here want’s someone local here as well to button it up and provide local support.

Specs are L71 on V28 and PV on V8.20.

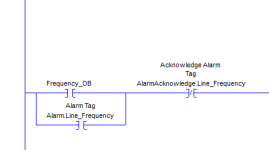

The thing I am stumped with at the moment is there are 546 alarms that need to be added to the PV, not a problem. However, the alarms are latched in the PLC program and require a bit to be toggled for each specific alarm to break the alarm condition rung.

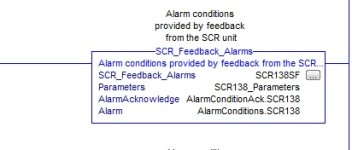

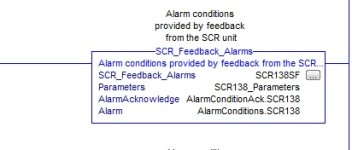

There are 78 CCI Power SCR’s over EtherNet/IP. Each has 7 alarms that can get latched, and 7 respective bits to clear the latch.

There is an AOI for the alarms and applied to the individual SCR’s. The AOI has the alarm latch and acknowledgement bit.

My question, does anyone have any insight as to what is going on here? This methodology is something I am not familiar with, and not sure of the intent.

I’ve been asked by a local company to drive 10 hours to finish programming and tuning a machine they had built by another company in NY so they can run off, tear down and ship to MI. The machine works, but needs to be finished.

Their programmer left for some reason, but the local company here want’s someone local here as well to button it up and provide local support.

Specs are L71 on V28 and PV on V8.20.

The thing I am stumped with at the moment is there are 546 alarms that need to be added to the PV, not a problem. However, the alarms are latched in the PLC program and require a bit to be toggled for each specific alarm to break the alarm condition rung.

There are 78 CCI Power SCR’s over EtherNet/IP. Each has 7 alarms that can get latched, and 7 respective bits to clear the latch.

There is an AOI for the alarms and applied to the individual SCR’s. The AOI has the alarm latch and acknowledgement bit.

My question, does anyone have any insight as to what is going on here? This methodology is something I am not familiar with, and not sure of the intent.