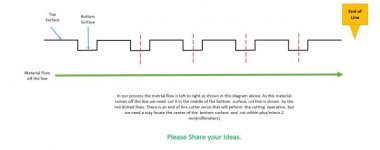

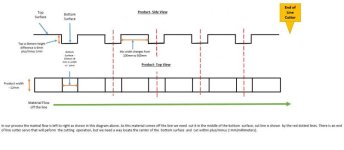

Cutting Solution Required - #PLC #Controls #Servo

- Thread starter msajid

- Start date

Similar Topics

Hi all,

Im having a weird problem with my panel and i think its the plc causing it but it could be some other component.

When i power up my...

Hello all,

We have a log oven with aluminium logs of 6m . I am trying to understand the program . THe log oven cuts the log according to the set...

Good Morning ,

Do you folks know of any Laser Manufactures that excel in the cutting of plastic film ? We are looking to upgrade our...

Greetings Everyone,

I am currently writing a program that controls a chemical reactioin chamber. At a certain point I need automatically control...

Hi...

I am using AB MPL-B540K with Kinetix6200 and CLX 1756-L72, 1756-M03SE sercos interface for flying shear application cutting metal sheet with...