once again - this is just GUESSWORK since we haven't seen the OP's program file ...

but ...

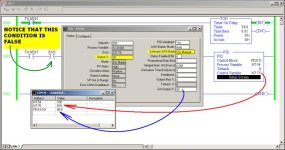

I'm pretty sure that the figure below shows the general ideas involved ... it would be well to keep in mind that the platform in question is a PLC-5 - and that there are significant differences between how that platform's PID is handled - when compared to the PID instruction for the SLC/MicroLogix platforms with which many people are more familiar ...

and along those lines, the PID instruction in the PLC platform normally gives its output signal in the range of 0 to 4095 ... so the value 819 shown at N7:75 (the CV) represents 20% of that range ...

also ...

as long as the PID rung stays FALSE (as shown) a value can be manually typed into the CV (N7:75) and the output signal to the field device will indeed change ...

but ...

if a value happens to be manually typed into the Set Output % location instead, then the output signal to the field device will NOT change ... which (if I'm interpreting the OP's post correctly) would be the condition that he is witnessing with his system ...

another big question is whether the OP is actually using the "Software Manual" mode - or the "Tieback" manual mode ... yes, the PID instruction for the PLC-5 platform has TWO (not just one) manual modes ... I'd say that fact might be contributing to the confusion here ...

finally - it would be nice to see the OP's actual program code - so that this "guesswork" could be eliminated ...

.