phuz

Member

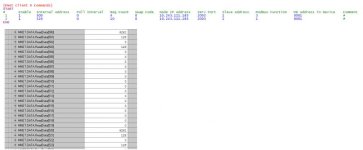

I'm re-writing a control scheme for some air compressors. Two of them have micrologix PLCs and the third is an Atlas Copco with MODBUS communications. It has a Lantronix RTU to Ethernet converter. I found a manual (http://read.pudn.com/downloads156/doc/comm/696115/UserGuideMkIVModbus01.pdf) that shows the registers I should need for all the control and status, so I configured the Prosoft module to read from its port 2003 on a few test registers. Unfortunately the data I am seeing in the CLX tables doesn't quite match what I would expect to see. I've tried byte swapping, word swapping, etc.

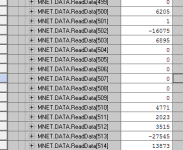

Further, even though I setup the Prosoft config for a register count of 5, it's filling 14 registers in the CLX table. And depending on which set of registers I attempt to read, some stay steady, while same flash a value and then return to 0.

Anyone have experience with this?

Further, even though I setup the Prosoft config for a register count of 5, it's filling 14 registers in the CLX table. And depending on which set of registers I attempt to read, some stay steady, while same flash a value and then return to 0.

Anyone have experience with this?

Last edited: