electric101

Member

Greetings,

I'm here in my home lab trying to acquire a working knowledge of UDT's. I've had to work with them in the past in large existing programs and they were a pain to track down and find out what IO they were really controlling. I have a decent understanding of what they are and I've created several to play with here using my softlogix processor and a digital flex IO rack.

My issue starts when i'm trying connect my UDT's to the physical IO. it looks like I cant use a simple move instruction (which would be way too easy and exactly what I need) I have a flex IO 8 point output. Local:1:O.Data[0]

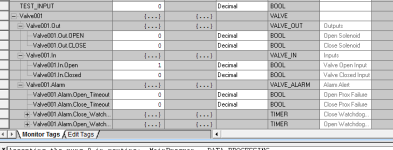

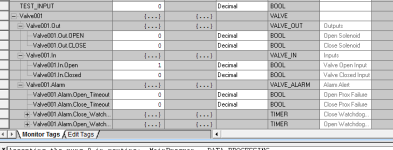

I have a UDT consisting of (see attachment)

Valve001

Valve001.Out

Valve001.Out.OPEN

Valve001.Out.CLOSE

Valve001.In

Valve001.In.OPEN

Valve001.In.CLOSED

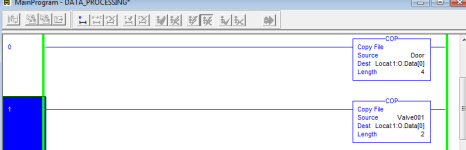

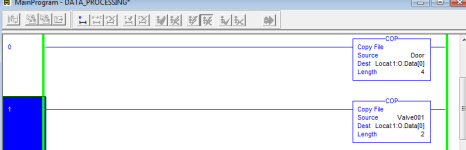

I have a copy instruction set to copy Valve001 to Local:1:O.Data[0] Length 2

that allows the Out.Open and Out.Close UDT's to control bits 0 and 1 of the 8 bit output . .... great.

Now I have another UDT setup to control lighting...

Door

Door.Out.OPEN

Door.Out.CLOSE

I want to control bits 2 and 3

I make another copy instruction in a line before the original copy instruction that states Copy Door to Local:1:O.Data[0] Length 4

but i'm really just fighting for the same 2 bits that the valve controls.... how can I control bits 2 and 3 for the door/lighting logic using these UDT's?

and that's not yet getting into having physical inputs moved/copied to the UDT input bits.

thanks!!

I'm here in my home lab trying to acquire a working knowledge of UDT's. I've had to work with them in the past in large existing programs and they were a pain to track down and find out what IO they were really controlling. I have a decent understanding of what they are and I've created several to play with here using my softlogix processor and a digital flex IO rack.

My issue starts when i'm trying connect my UDT's to the physical IO. it looks like I cant use a simple move instruction (which would be way too easy and exactly what I need) I have a flex IO 8 point output. Local:1:O.Data[0]

I have a UDT consisting of (see attachment)

Valve001

Valve001.Out

Valve001.Out.OPEN

Valve001.Out.CLOSE

Valve001.In

Valve001.In.OPEN

Valve001.In.CLOSED

I have a copy instruction set to copy Valve001 to Local:1:O.Data[0] Length 2

that allows the Out.Open and Out.Close UDT's to control bits 0 and 1 of the 8 bit output . .... great.

Now I have another UDT setup to control lighting...

Door

Door.Out.OPEN

Door.Out.CLOSE

I want to control bits 2 and 3

I make another copy instruction in a line before the original copy instruction that states Copy Door to Local:1:O.Data[0] Length 4

but i'm really just fighting for the same 2 bits that the valve controls.... how can I control bits 2 and 3 for the door/lighting logic using these UDT's?

and that's not yet getting into having physical inputs moved/copied to the UDT input bits.

thanks!!