f16bmathis

Member

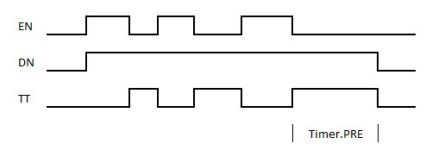

I need to set a timer to start timing, and reset and continue timing if a PE is blocked before the timer times out. Sounds simple? Probably is, but I'm using the DN to keep it running, and as soon as its done, it resets and continues to run even with the PE no longer blocked.

Basic idea is as product passes by, a solenoid stays on. If product stops running by, after 5 or so seconds the solenoid shuts off. PLC runs 500.

Any help before I tear my hair out appreciated!

Basic idea is as product passes by, a solenoid stays on. If product stops running by, after 5 or so seconds the solenoid shuts off. PLC runs 500.

Any help before I tear my hair out appreciated!