g.mccormick

Lifetime Supporting Member

Potential project will have a sample jar that will need to be automatically filled. As of right now, I believe that the jars will be clear glass or plastic. I want to detect that the jar is in place, and then fill the jar to a level and detect when it is full.

The liquid will be engine oil.

For the jar inplace sensor I am thinking a capacitive prox switch.

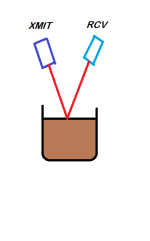

For the full level in the jar, I'm thinking perhaps photoelectric. Would diffuse photoelectric be a good match?

I'm sure someone has worked through this before. Anyone have suggestions?

The liquid will be engine oil.

For the jar inplace sensor I am thinking a capacitive prox switch.

For the full level in the jar, I'm thinking perhaps photoelectric. Would diffuse photoelectric be a good match?

I'm sure someone has worked through this before. Anyone have suggestions?