cartierusm

Member

I'm trying to control a tool changer on my retrofit CNC lathe that I built. I have experience with PLCs, but not much. I'm using a click PLC.

The tool changer has 5 proximity switches, NPN, and a combination of 3 of those switches ON is a position.

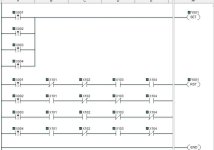

Look at the pics. When I write a program for a single position, such as the first pic, it works of course, but I can't figure out how to program it so I can press a different button to have it stop on different positions.

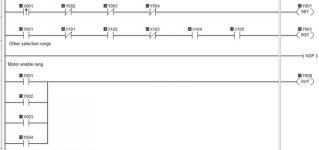

The second pic show basically what I want to happen. Any help would be appreciated.

The tool changer has 5 proximity switches, NPN, and a combination of 3 of those switches ON is a position.

Look at the pics. When I write a program for a single position, such as the first pic, it works of course, but I can't figure out how to program it so I can press a different button to have it stop on different positions.

The second pic show basically what I want to happen. Any help would be appreciated.