Hello,

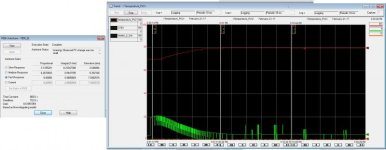

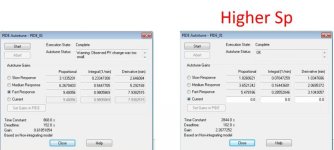

I am trying to modify an existing program because the temperature is not stable (according to the operator it was never precise). So, I decided to use PIDE instruction along with a SRTP block to do the job. When I tried the autotune feature I received the following warning “Warning: Observed PV change was too small., Warning: Identified process gain is too small., Warning: Long deadtime process identified.”

I changed the CV Step size to different values (10, 20, 40& 80%) but I receive the same warnings and none of the slow, medium and fast response gave me a good result. This is my first time using the PIDE, I believe that I am doing something wrong. I attached the file. Thanks in advance for any inputs.

I am trying to modify an existing program because the temperature is not stable (according to the operator it was never precise). So, I decided to use PIDE instruction along with a SRTP block to do the job. When I tried the autotune feature I received the following warning “Warning: Observed PV change was too small., Warning: Identified process gain is too small., Warning: Long deadtime process identified.”

I changed the CV Step size to different values (10, 20, 40& 80%) but I receive the same warnings and none of the slow, medium and fast response gave me a good result. This is my first time using the PIDE, I believe that I am doing something wrong. I attached the file. Thanks in advance for any inputs.