Saturn_Europa

Member

RS Logix 5000 v20.04 Contol Logix L-7 Processor

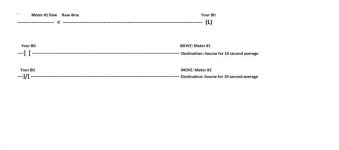

I have been tasked with recording the highest daily turbidity value on a reclaim water system. I am going to take a 10 second moving average and compare it to the previous 10 second moving average and keep the highest one. (Still trying to figure out how to reset it after 24 hrs). Suggestions?

There are two turbidity meters on this system. One for primary and one for backup. Is there a slick way to select between which turbidity meter the program will use for calculation? I would like the program to de-select the meter if it starts giving bad readings. Obviously anything under 4 mA would indicate a bad reading. Has anyone done this before?

I have been tasked with recording the highest daily turbidity value on a reclaim water system. I am going to take a 10 second moving average and compare it to the previous 10 second moving average and keep the highest one. (Still trying to figure out how to reset it after 24 hrs). Suggestions?

There are two turbidity meters on this system. One for primary and one for backup. Is there a slick way to select between which turbidity meter the program will use for calculation? I would like the program to de-select the meter if it starts giving bad readings. Obviously anything under 4 mA would indicate a bad reading. Has anyone done this before?