jolio ST

Member

I have a slight problem whie doing a programming on RSLogix500. I have an input that comes from a selector switch, "auto" or "manual", to the PLC.

I have 2 outputs from the PLC, wired to 2 relays, one of them outputs to a motorised speed adjustment (for auto) and another to a hand-tuned potentiometer (for manual). This speed adjustment is to regulate the speed of the running engine.

The problem now is that when my engine is running, I need to turn it to the other selection, no matter if my selection now is Auto or Manual. When I changed the selection, it will experience a momentum of an open circuit, thus putting an emergency stop the the engine, and I will have an over-speed fault. So I need a timer to hold the relay that was energised first, as well as to energise the selected relay. This way I will have the effect of a "make-before-break", and thus not endangering my running engine.

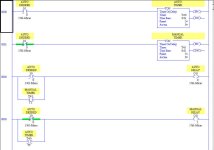

I added the follow ladder to my program. I tried it the previous time with latches, but I can't get the result I need. Someone have a look at the following and help me comment, please?

I have been fixing many glitches in this engine control panel since morning 10am. I'm still working now at 9pm and I'm beat. x_x

Thank you very much!

regards

ST

I have 2 outputs from the PLC, wired to 2 relays, one of them outputs to a motorised speed adjustment (for auto) and another to a hand-tuned potentiometer (for manual). This speed adjustment is to regulate the speed of the running engine.

The problem now is that when my engine is running, I need to turn it to the other selection, no matter if my selection now is Auto or Manual. When I changed the selection, it will experience a momentum of an open circuit, thus putting an emergency stop the the engine, and I will have an over-speed fault. So I need a timer to hold the relay that was energised first, as well as to energise the selected relay. This way I will have the effect of a "make-before-break", and thus not endangering my running engine.

I added the follow ladder to my program. I tried it the previous time with latches, but I can't get the result I need. Someone have a look at the following and help me comment, please?

I have been fixing many glitches in this engine control panel since morning 10am. I'm still working now at 9pm and I'm beat. x_x

I:4/8 T4:49/DN B3:4/1

---||-------|/|------------( )

B3:4/1 T4:48 TOF

---||----------------------[ ] 50 M.SEC

T4:48/DN T4:49/DN O:7/3

---||-------|/|------------( )

T4:49/DN T4:48/DN O:8/14

---|/|-------||------------( )

I:4/8 B3:4/2

---|/|----|----------------( )

T4:48/DN |

|---||----|

B3:4/2 T4:49 TOF

---||----------------------[ ] 50 M.SEC

Thank you very much!

regards

ST