panel1

Member

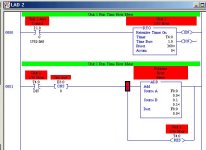

I need a better way to capture elapsed runtime on a motor? Im using a Micrologix 1200 with real time clock onboard. How can the RTC be used in this function. Thanks for your help. Im new to PLC's and this forum.

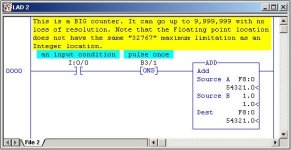

PS... how can I count past 32767 on my counter?

attached file is RSlogix 500

PS... how can I count past 32767 on my counter?

attached file is RSlogix 500