Tim Moulder

Guest

T

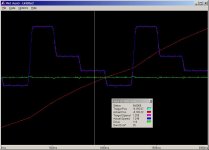

You are monitoring a pulse train with a high speed counter. You are tracking both frequency and pulse count. The signal ranges from 180Hz to 500Hz. Noise is about +/- 10Hz at any given frequency.

The frequency will change 4 times, by at least 50Hz, but usually more. When the frequency changes, record the pulse count and new frequency. Absolute accuracy is not essential, but the closer, the better.

Now the caveat: you cannot predict when the frequency will change, based on pulse count. It can change at any time. You must detect the change, record the pulse count, and the new stable frequency.

I've been battling this one for two days now. I've tried using a 1 second timer to look for stable frequency, then "passing back" one second's worth of pulses to the previous count, but that isn't working out.

Somehow, I can't shake the feeling there should be a very easy way to do this in ladder...

TM

The frequency will change 4 times, by at least 50Hz, but usually more. When the frequency changes, record the pulse count and new frequency. Absolute accuracy is not essential, but the closer, the better.

Now the caveat: you cannot predict when the frequency will change, based on pulse count. It can change at any time. You must detect the change, record the pulse count, and the new stable frequency.

I've been battling this one for two days now. I've tried using a 1 second timer to look for stable frequency, then "passing back" one second's worth of pulses to the previous count, but that isn't working out.

Somehow, I can't shake the feeling there should be a very easy way to do this in ladder...

TM