Guest

Guest

G

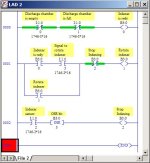

I am attempting to find a solution for a program that I have to put together. First off, it has been several years since I have worked with a PLC, mostly I have been using single board computers. I dont recall how to work everything out in ladder, I have been using code/line based stuff for too long I guess.

What I am doing is this:

I have a rotary indexer that I am building. It is for metering part flow through a system. The indexer looks like the chamber for a revolver. I have 3 sensors hooked to the indexer. 2 sensors for part presence (the chamber they are loaded in and the chamber they exit from) and another prox switch to tell me when to stop rotating the indexer.

What I would like to do is this:

first part loads and trips the first sensor

check to see that the discharge is clear (sensor 2)

rotate the indexer 1 chamber, stop rotating when the prox (sensor #3) trips

first part exits the chamber in position #2 and clears sensor #2 while the second part loads into the indexer.

Sensor #1 is triped by the second part. Rotate the indexer when part #1 clears sensor #2. Continue rotating the indexer until the prox trips on the next chamber.

Logically, when sensor #1 is tripped and sensor #2 is not, latch the output to the motor on until sensor #3 trips. Repeate. My problem is that sensor #3 is on any time the indexer is not moving and is still on for the first few degrees of rotation. so that logic does not quite work. The output will essentally only be on for one scan and constantly be switching on and off each scan cycle.

I am using an Allen Bradly micrologix plc with RSlogix 500. I would think this would be fine if I could just have the rung that is looking for the prox to stop the motor look for the edge of my sensor but I do not see any paticular controls for doing that.

Again, I am not that framilliar with PLCs and this is the first time I have tried using an Allen Bradly PLC. This is probably somthing super simple and I just don't know where to look for the function.

Thank you in advance for the assistance!

Cheers

Spike

What I am doing is this:

I have a rotary indexer that I am building. It is for metering part flow through a system. The indexer looks like the chamber for a revolver. I have 3 sensors hooked to the indexer. 2 sensors for part presence (the chamber they are loaded in and the chamber they exit from) and another prox switch to tell me when to stop rotating the indexer.

What I would like to do is this:

first part loads and trips the first sensor

check to see that the discharge is clear (sensor 2)

rotate the indexer 1 chamber, stop rotating when the prox (sensor #3) trips

first part exits the chamber in position #2 and clears sensor #2 while the second part loads into the indexer.

Sensor #1 is triped by the second part. Rotate the indexer when part #1 clears sensor #2. Continue rotating the indexer until the prox trips on the next chamber.

Logically, when sensor #1 is tripped and sensor #2 is not, latch the output to the motor on until sensor #3 trips. Repeate. My problem is that sensor #3 is on any time the indexer is not moving and is still on for the first few degrees of rotation. so that logic does not quite work. The output will essentally only be on for one scan and constantly be switching on and off each scan cycle.

I am using an Allen Bradly micrologix plc with RSlogix 500. I would think this would be fine if I could just have the rung that is looking for the prox to stop the motor look for the edge of my sensor but I do not see any paticular controls for doing that.

Again, I am not that framilliar with PLCs and this is the first time I have tried using an Allen Bradly PLC. This is probably somthing super simple and I just don't know where to look for the function.

Thank you in advance for the assistance!

Cheers

Spike