leitmotif

Member

As I have said I am trying to learn PLCs.

My first effort was taking a Siemens unit I had out of storage and use it to learn with. The manuals that came with it were not much help and I was chicken and afraid of blowing it up.

One HUGE lesson I learned was that with no input hooked up I got an output LED. This showed me I had a lot to learn to avoid this dangerous condition. If I recall correctly this was with an input configured as a normally closed contact.

I contacted you guys asking for more study material. YOu referred me I used it and it helped. Once again thanks.

I found a class at North Seattle Community College on PLCs, enrolled and start next week.

In meantime I am reading the textbook Introduction to Programmable LOgic Controllers by Gary Dunning.ISBN 0 8273 7866. This is the first version and the class is using the second version. I also intend to buy the second version - I am evaluating the book courtesy of the County Library.

AT LAST the question

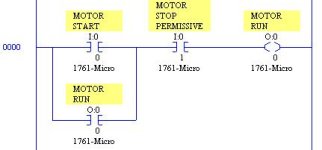

on pp 305 309 he discusses the start stop switches (momentary on and momentary off) for motor control. He makes the point the stop (normally closed or momentary off) should be a fail safe such that any failure will shutdown the equipment (broken wire etc etc). Completely agree.

Here is where I get confused and seems to touch on the experience I had with the Siemens (no connected input and an output LED). He is using the Rockwell SLC 500 or micrologix 1000 instructions. He recommends configuring the STOP switch (momentary Norm Closed) as if it were a normally open using ROCWELL XIC (examine if closed) instruction.

I can sort of see the reasoning behind it but keep wondering why I should call a normally closed switch (hardwired) a normally open in the software. If his recommendatin on p 309 work -- why have a normally closed software coniguration in the software if it cannot be used directly to a normally closed switch (hardwired).

I intend to bring my dilemna up in class and get a clear understanding on it.

In the meantime I want to hear from the "guys in the real world" who have been thru the dilemna and how they coame to understand it and not get confused.

Dan

My first effort was taking a Siemens unit I had out of storage and use it to learn with. The manuals that came with it were not much help and I was chicken and afraid of blowing it up.

One HUGE lesson I learned was that with no input hooked up I got an output LED. This showed me I had a lot to learn to avoid this dangerous condition. If I recall correctly this was with an input configured as a normally closed contact.

I contacted you guys asking for more study material. YOu referred me I used it and it helped. Once again thanks.

I found a class at North Seattle Community College on PLCs, enrolled and start next week.

In meantime I am reading the textbook Introduction to Programmable LOgic Controllers by Gary Dunning.ISBN 0 8273 7866. This is the first version and the class is using the second version. I also intend to buy the second version - I am evaluating the book courtesy of the County Library.

AT LAST the question

on pp 305 309 he discusses the start stop switches (momentary on and momentary off) for motor control. He makes the point the stop (normally closed or momentary off) should be a fail safe such that any failure will shutdown the equipment (broken wire etc etc). Completely agree.

Here is where I get confused and seems to touch on the experience I had with the Siemens (no connected input and an output LED). He is using the Rockwell SLC 500 or micrologix 1000 instructions. He recommends configuring the STOP switch (momentary Norm Closed) as if it were a normally open using ROCWELL XIC (examine if closed) instruction.

I can sort of see the reasoning behind it but keep wondering why I should call a normally closed switch (hardwired) a normally open in the software. If his recommendatin on p 309 work -- why have a normally closed software coniguration in the software if it cannot be used directly to a normally closed switch (hardwired).

I intend to bring my dilemna up in class and get a clear understanding on it.

In the meantime I want to hear from the "guys in the real world" who have been thru the dilemna and how they coame to understand it and not get confused.

Dan