foreword: I wrote the stuff below before I read your latest post ... I'll read that now ... some of what I've written might change but this will help get us started ... also: if you want to, you can send me a Private Message with your phone number ... I'll give you a call and try to talk you through some of this ... this typing is killing me ... I'll be here for about 30 more minutes then offline for the weekend ... sorry but my boss won't let me send you my number ... the last time I gave that out, the guy posted it as part of his "thank you" and I got way too many "help me" calls from people I'd never heard of ...

and so:

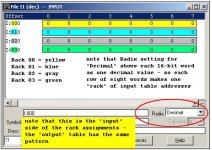

and here’s a little screen shot that might help make the PLC-5’s addressing scheme a little more understandable ...

[attachment]

in this “decimal” display mode, each colored horizontal bar is one-half of a “rack” – specifically 8 words on the input table ... don’t forget the “output” side of the “rack” definition ... the first two digits in each word’s address indicate the “rack” number ... example: in “I:000” or “I:001” the digits “00” indicate that these words are located in rack 00 ... in “I:024” or “I:026” the digits “02” indicate that these words are located in rack 02 ...

note that this is an example of a PLC-5/20 processor ... a larger type processor (example: PLC-5/80) would have many more racks of I/O on this chart ...

in the PLC-5 system, “rack 00” is always reserved for “Local I/O” ... specifically, I/O which resides in the same chassis with the processor ... you cannot assign either one of your drives to this particular rack because they are not LOCAL I/O – they are REMOTE I/O ...

going further ... you MIGHT be able to assign your drives to “rack 01” and/or to “rack 02” ... but then again you might not ... depending on how your local addressing is set up (two-slot, one-slot, or half-slot) and on how large the local chassis is (example: 8-slots, 16-slots, etc.), then the rack assignments for “rack 01” and/or “rack 02” might also already be taken up for local I/O ... that’s why I recommend that you post your .RSP program files ... we can usually tell enough from those to figure out what assignments are - and are not – available ...

sanity check: I’ve already mentioned that this is quite a big subject ... we can help you through it but it’s not going to be as “quick and easy” as you might hope ... some people complain that the Allen-Bradley addressing scheme is the most complicated and convoluted system in existence ... I won’t argue that point one way or the other ... but other people point out how incredibly flexible it is ... and I won’t argue that point either ... regardless of how well you do - or do not – like the system, these are some of the issues involved ... like they say: “if it was easy, everybody could do it” ...

so how about calling in your local distributor? ... how’s that idea starting to sound? ...

plan of attack: post the information I asked for and we’ll get started ... by the way, what’s your deadline on this project? ... note that “as soon as possible” is not a valid answer ...