shandra_ck

Guest

S

Hi all,

I am a new member and I found this website is very useful.

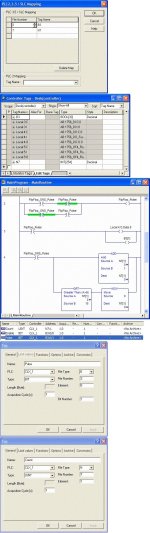

I do have a question on Alan Bradley PLC 5 and need some assitant.

How do I program the PLC 5 to work with Siemens OP 7?

What softwares do I need and how do I configure that in Pro Tool?

I really hope that someone can help me.

Thank you.

Best regards,

Shandra

I am a new member and I found this website is very useful.

I do have a question on Alan Bradley PLC 5 and need some assitant.

How do I program the PLC 5 to work with Siemens OP 7?

What softwares do I need and how do I configure that in Pro Tool?

I really hope that someone can help me.

Thank you.

Best regards,

Shandra