You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

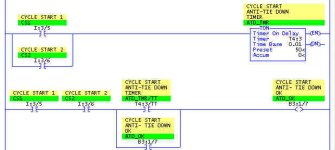

anti tie-down circuit

- Thread starter darren

- Start date

Mike Williams

Member

I think you are talking about a circuit which requires an operator to have both hands on start switches in order to begin a machine cycle. This minimizes the possibility of an operator having a hand in the work area when a machine cycle is started. If one or both switches are "tied-down", the control will not allow a new machine cycle to begin.

The circuit is not complicated, what it does is important. This should be enough info for you to give it a shot. Post what you try and you will get help.

The circuit is not complicated, what it does is important. This should be enough info for you to give it a shot. Post what you try and you will get help.

john paley

Member

Yes. I can tell you what it should do, but you figure out how to code it, OK?

The idea is to have two push buttons, usually palm buttons on a machine that operates in a specific cycle. These buttons should be physically located so that the operator must use both hands to operate both buttons. The operator must operate both buttons simultaneously to start the cycle, and hold them both until the cycle progresses to some "safe point"--i.e. where the operator cannot physicaly get his hand(s) into the pinch point. He then may release the buttons and the cycle will complete. For a punch press, this "safe point" would be when the die closes at the bottom of the stroke. For some machines this "safe point" may well be the end of the cycle.

Now for the anti tie down / anti repeat. If the operator holds the buttons throughout the cycle, the machine must stop at completion of the cycle. Before the cycle may be started again, BOTH buttons must be fully released and re applied. This prevents the operator from running the machine in a "continuous" cycle. It also prevents him from "tying" down one of the two buttons and operating the machne one-handed.

Easy to do in PLC ladder logic, although not legal, I think, for lots of machinery, like presses, which require a lot of redundant circuitry.

The idea is to have two push buttons, usually palm buttons on a machine that operates in a specific cycle. These buttons should be physically located so that the operator must use both hands to operate both buttons. The operator must operate both buttons simultaneously to start the cycle, and hold them both until the cycle progresses to some "safe point"--i.e. where the operator cannot physicaly get his hand(s) into the pinch point. He then may release the buttons and the cycle will complete. For a punch press, this "safe point" would be when the die closes at the bottom of the stroke. For some machines this "safe point" may well be the end of the cycle.

Now for the anti tie down / anti repeat. If the operator holds the buttons throughout the cycle, the machine must stop at completion of the cycle. Before the cycle may be started again, BOTH buttons must be fully released and re applied. This prevents the operator from running the machine in a "continuous" cycle. It also prevents him from "tying" down one of the two buttons and operating the machne one-handed.

Easy to do in PLC ladder logic, although not legal, I think, for lots of machinery, like presses, which require a lot of redundant circuitry.

plc anti tie down

Thanks Big Cheese and Mike Williams for your responses. Yes, that is what was meant by anti tie down. I've already completed it in relay logic, it's just that we have to convert it to plc's and we don't have a lot of resources at our disposal to figure it out. I'll try to work it out, though, and I thank you again for taking the time.

Darren

Thanks Big Cheese and Mike Williams for your responses. Yes, that is what was meant by anti tie down. I've already completed it in relay logic, it's just that we have to convert it to plc's and we don't have a lot of resources at our disposal to figure it out. I'll try to work it out, though, and I thank you again for taking the time.

Darren

Eric Nelson

Lifetime Supporting Member + Moderator

john paley said:The operator must operate both buttons simultaneously to start the cycle...

Just to clarify this for Darren. As far as anti tie-downs go, simultaneously means "within a 1/2 second of each other".

I doubt you'll find an operator that can operate both buttons at EXACTLY the same time. I've seen quite a few operators that can't even do it in the 1/2 second window...

By the way, that's also a hint for Darren that you'll need to use timers!...

beerchug

-Eric

David_Emmerich

Lifetime Supporting Member

You might also check out and look at their two hand switch set-ups...might give you some ideas..OPTO-Touch.....

David

David

jdbrandt

Lifetime Supporting Member

these are made in hardware

FYI, IMHO, for anti-tiedown, I'd never program it

where Safety, liability, etc. were involved.

There's a sub-$200.00 module made by NOLATRON (and

maybe others, I don't know) that does it all,

including the latching or unlatching feature.

I will say that a NOLATRON uses the N.O. contact and the

N.C. contact of the pushbutton.

See where that leads you.

FYI, IMHO, for anti-tiedown, I'd never program it

where Safety, liability, etc. were involved.

There's a sub-$200.00 module made by NOLATRON (and

maybe others, I don't know) that does it all,

including the latching or unlatching feature.

I will say that a NOLATRON uses the N.O. contact and the

N.C. contact of the pushbutton.

See where that leads you.

ganutenator

Lifetime Supporting Member

rogerhollingsworth

Member

Safety

As John mentioned, that and other issues with safety are not permitted to be done VIA PLC or control. Emergency stops, Anti Tiedowns and safety Lock-outs just to name a few. Although they can be diplicated in the PLC for status.

As John mentioned, that and other issues with safety are not permitted to be done VIA PLC or control. Emergency stops, Anti Tiedowns and safety Lock-outs just to name a few. Although they can be diplicated in the PLC for status.

rsdoran

Lifetime Supporting Member

That isnt totally correct, there are a few PLC's designed to work with safety. AB has the GuardPLC's (which they bought from another company that is still being sold thru others as are some of their light curtains etc).

Safety issues look at redundant factors and a plc can provide those BUT when using a plc for safety issues it is not to do process work...ie it can only do the things involved with safety.

I have had to attend an abundance of seminars/training recently because of corporation issues on safety. At the same time I have to deal with engineers that do not seem to care (I suspect budget issues) about code/osha issues on what is suppose to be done to conform to the rules/guidelines.

There are many tools out there to use, it takes alot of time/energy to determine what to use.

Safety issues look at redundant factors and a plc can provide those BUT when using a plc for safety issues it is not to do process work...ie it can only do the things involved with safety.

I have had to attend an abundance of seminars/training recently because of corporation issues on safety. At the same time I have to deal with engineers that do not seem to care (I suspect budget issues) about code/osha issues on what is suppose to be done to conform to the rules/guidelines.

There are many tools out there to use, it takes alot of time/energy to determine what to use.

steffen_sohl

Lifetime Supporting Member

I don't know how it is with AB GuardPLC, but I've worked with Pilz, there you have to use a Programme-block which i is Certified.

Using a Saftety PLC is no guarantee for that the code is right !!!!

beerchug

Steffen

Using a Saftety PLC is no guarantee for that the code is right !!!!

beerchug

Steffen

rogerhollingsworth

Member

Safety

I must not be up to date on my safety. I thought O.S.H.A. insisted that emergency stops & lockouts were to be hardwired. If they have strayed from that I think it is a mistake.

Thanks

Roger

I must not be up to date on my safety. I thought O.S.H.A. insisted that emergency stops & lockouts were to be hardwired. If they have strayed from that I think it is a mistake.

Thanks

Roger

Alan Case

Lifetime Supporting Member

Roger. PLC control of a safety circuit is possible. BUT it is not done with any normal PLC. The Pilz and the AB safety PLCs are programmed with function blocks that are certified by a relevant authority, the controllers themselves use at least 2 processors that must match on the decision and the inputs are as far as I can remember are duplicated. Regards Alan Case

rogerhollingsworth

Member

Safety

Thanks Allen, Just wasn't aware, which isn't an unusual position for me these days.

Have a good one or two.

Roger

Thanks Allen, Just wasn't aware, which isn't an unusual position for me these days.

Have a good one or two.

Roger

Rick Densing

Member

Similar Topics

Good day all. I have a machine to automate. It is a 2-ton heat press. It moulds small plastic parts. The mould cycle is initiated after the...

- Replies

- 6

- Views

- 3,075

I searched and could not find an answer.

The machine is a pneumatic press,two cylinders 32mm bore.

Can this machine be built per OSHA safety...

- Replies

- 7

- Views

- 3,727

Hello, I am in school learning about PLC and RLL and my professor gave us an assignment to try to figure out how to write code for a anti tie down...

- Replies

- 85

- Views

- 30,001

Can someone show me an example of an anti tie down program? I am using micrologix 1200.

- Replies

- 3

- Views

- 5,724

I am setting up an educational work cell in my University's automation lab. It is a senior thesis project and will be used for educational...

- Replies

- 28

- Views

- 8,627