No, all these do not mean the same thing.

There may be more than one explanation for wet/dry contacts but I will share what I am familiar with.

A dry set of contacts is what you normally have on your standard relay or auxiliary.

A wet set of contacts would be found in a mercury switch.

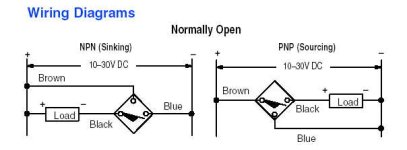

Sinking and sourcing are terms used to describe how an associated load (the device being turned on or off by the sensor) is powered in relation to the sensor. Sinking, the more widely used of the two, involves the switching of load current (power) supplied by a power source external to the sensor. In a sinking configuration, current passes through the load first, through the output switch of the sensor second and lastly to ground. A sensor with a sinking output switches the ground, or negative, leg of the circuit. In contrast, sourcing refers to a configuration in which the sensor is the source of the current required to power the load. In a sourcing situation, current supplied by the sensor passes through the load second and then to ground. A sensor with a sourcing output switches the positive leg of the circuit.

NPN transistor; You feed a little bit of current in the base leg and it turns on to let a lot of current flow through it.

PNP transistor; You to let a bit of current flow out of the base leg to make a lot of current flow through it.

There's something else you can do with NPN and PNP transistors. If a circuit only contains one type, you can replace it with the other type, providing you reverse the polarity of the supply.

Hope this helps

Roger