Andrew Evenson

Member

Hi all,

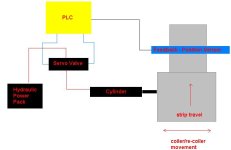

Has anyone ever done an installation where edge guiding for coilers/re-coilers were done in a PLC, where a manufacture's sensors were used and either the a stand alone hydrualic power pack or a process's hydraulic system was used as the prime mover to a cylinder?

I know most manufactuers dont like to sell just there sensors without there controllers, but this is a system in all out lines we are looking to integrate into the plc, because of manintance and spare parts, as the systems we have right now are OLD, and parts are not made anymore for them. Has anyone dont something like this or seem anything like this?? What sensors were used, as in manufacture's names?? We arnt sure if we are going for a emitter/reciever pair just looking at the edge of the strip or a capacitance/inductance sensor looking at the total width of the strip or a camera system..I hope someone understands what I just described, and I will put a sketch together and add it to this post..

Thanks for any suggestions in advance..

Andrew

Has anyone ever done an installation where edge guiding for coilers/re-coilers were done in a PLC, where a manufacture's sensors were used and either the a stand alone hydrualic power pack or a process's hydraulic system was used as the prime mover to a cylinder?

I know most manufactuers dont like to sell just there sensors without there controllers, but this is a system in all out lines we are looking to integrate into the plc, because of manintance and spare parts, as the systems we have right now are OLD, and parts are not made anymore for them. Has anyone dont something like this or seem anything like this?? What sensors were used, as in manufacture's names?? We arnt sure if we are going for a emitter/reciever pair just looking at the edge of the strip or a capacitance/inductance sensor looking at the total width of the strip or a camera system..I hope someone understands what I just described, and I will put a sketch together and add it to this post..

Thanks for any suggestions in advance..

Andrew