Alright, I've read another post where it was said that you don't mind helping students, but you don't hand out freebees. Well, I'm a student in need of help. I'm trying my best to find the answer, but I'm not doing so well. I'd appriciate some help.

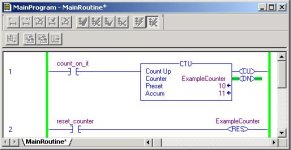

The Question: When using an up/down counter with a preset value of 10, what would happen if 11 pulses come into the counter before it is reset? What happens to the extra pulse?

The only info. I can find is "Again note that the counter accumulated value ONLY changes at the off to on transition of the pulse input. "

My interpretation is that the counter would change at 10, so it should never get to 11. However, the wording of the question implies that I am wrong. I can't find anyother relivent info.

Any help? <-----Looking sad in hope that you will take pity on me

<-----Looking sad in hope that you will take pity on me

The Question: When using an up/down counter with a preset value of 10, what would happen if 11 pulses come into the counter before it is reset? What happens to the extra pulse?

The only info. I can find is "Again note that the counter accumulated value ONLY changes at the off to on transition of the pulse input. "

My interpretation is that the counter would change at 10, so it should never get to 11. However, the wording of the question implies that I am wrong. I can't find anyother relivent info.

Any help?