You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Siemens S7 v RSLogix500

- Thread starter Jezz

- Start date

Hi Jezz,

We too have mainly AB plc-5,SLC 500,but we do use siemens S7 on some small applications,the basic control is nearly the same although siemens works in 8 bit format unlike AB 16 bit,but when you get to using more complicated maths there is quite a big difference,all the software is supposed to be iec standard but funnily enough when it comes to advanced using you seem to need to go and do a vendor course to understand it completely.(a money spinner)!!!!!!!!!!!

Personnaly myself i find AB software more user friendly and more functional than siemens S7.

We too have mainly AB plc-5,SLC 500,but we do use siemens S7 on some small applications,the basic control is nearly the same although siemens works in 8 bit format unlike AB 16 bit,but when you get to using more complicated maths there is quite a big difference,all the software is supposed to be iec standard but funnily enough when it comes to advanced using you seem to need to go and do a vendor course to understand it completely.(a money spinner)!!!!!!!!!!!

Personnaly myself i find AB software more user friendly and more functional than siemens S7.

TimeFluxCap

Member

Jezz, after learning myself using mainly AB RSLogix the hardest thing I found about S7s when I first looked at them was Function Blocks and Data Blocks. On your Simatic cd there is a "Getting Started, working with S7 Appendix A" pdf file. It steps you through all the basics.

I did it myself page by page to learn. Just print it out and get cracking.

I did it myself page by page to learn. Just print it out and get cracking.

Jezz,

I'm teaching both Siemens Step 7 and AB CompactLogix to unemployed. The Siemens stuff I started 10 years agoo, with the old S5's, and since 5 years I also teach S7-300 for which I wrote a couple of courses.

Two years agoo I started with AB CompactLogix and nowadays I'm busy writing my own course on AB SLC500.

The main differences between Siemens and AB are:

Hope this helps,

Jean Pierre Vandecandelaere

Trainer PLC - SCADA

VDAB Bruges

Belgium

http://vdab.be

I'm teaching both Siemens Step 7 and AB CompactLogix to unemployed. The Siemens stuff I started 10 years agoo, with the old S5's, and since 5 years I also teach S7-300 for which I wrote a couple of courses.

Two years agoo I started with AB CompactLogix and nowadays I'm busy writing my own course on AB SLC500.

The main differences between Siemens and AB are:

- blocks with parameters are easier in Siemens

- you can easily translate Siemens blocks from ladder to STL to FBD (try this with AB)

- communication is a lot easier with AB

- and yes garryt1, Siemens is byte oriented and AB is word oriented. But Siemens also knows word and even doubleword formats. These are made up of consequent bytes and you have to get used to the hows and whys.

Hope this helps,

Jean Pierre Vandecandelaere

Trainer PLC - SCADA

VDAB Bruges

Belgium

http://vdab.be

seppoalanen

Member

I have prorgrammed since 1978 by Simatic and Allen Bradley.

Simatic-Step-languages are as assembler and CtrlLogix is more high level language as Java or VBasic. Main point is that structures are easyly possible in AB and not need know anything of absolute memory addresses.

High level languages have done 50 years ago (Cobol), becourse assembler is so difficult for application development.

We are doing applications!

Profibus, MPI and Simatic allover are polling systems. ControlLogix5000 is event base where I/O-units sends contents to PLC only when something have changed. DeviceNet and ControlNet can use change of state (COS) so field devices sends information only when something have changed and bus is free for more necessary 'trafic'.

If I have to program some system by Simatic where are much mathematics or datahandling/database connections, my programming price is 2-times more than by A-B.

Simatic-Step-languages are as assembler and CtrlLogix is more high level language as Java or VBasic. Main point is that structures are easyly possible in AB and not need know anything of absolute memory addresses.

High level languages have done 50 years ago (Cobol), becourse assembler is so difficult for application development.

We are doing applications!

Profibus, MPI and Simatic allover are polling systems. ControlLogix5000 is event base where I/O-units sends contents to PLC only when something have changed. DeviceNet and ControlNet can use change of state (COS) so field devices sends information only when something have changed and bus is free for more necessary 'trafic'.

If I have to program some system by Simatic where are much mathematics or datahandling/database connections, my programming price is 2-times more than by A-B.

Hi Jezz,

I say that they are quite different.

STEP7 has a more rigid "feel", compared to RSLogix.

The STEP7 manuals can be a little confusing, as the translation from german makes for some strange instructions.

Siemens has just released a new version of STEP7 (v5.2) that should be much easier to use (they say). STEP7 lite (for S7-300) should allready have this easy-to-use makeover.

The most important differences are:

1. RSLogix is only LADDER,

STEP7 is STL (statement list), LAD and FBD (logic funtion blocks).

Notice: STL can not allways be converted to LAD or FBD.

2. RSLogix does not format variables into types.

STEP7 requires that variables define their type (word, int, real etc.)

It's a pain in the ... But on the other hand it will catch potential errors at edit-time.

3. RSLogix is quite "conventional" with regards to the program structure. STEP7 allows you to make reusable code via parameterizable subroutines. You will spend more time in the beginning, but it will pay back later.

4. RSLogix is great for doing math, especially with the COMPUTE instruction. STEP7 is just as capable, but is a LOT more rigid. You have to convert between INT's and DOUBLE's and REAL's as you go.

Count on 2-5 times as long time for programming math in STEP7 as compared to RSLogix.

5. RSLogix and STEP7 does online viewing of the program a little differently. RSLogix displays the variable content asyncronously to the program scan. STEP7 displays the variables strictly syncronously with the program scan. Good: It shows the data as they change instruction for instruction. Bad: If the rung or isntruction isn't executed, the data will not be displayed at all.

6. The STEP7 program simulator PLC-SIM is better (and cheaper) than AB's simulator. AB will not allow you to make online editing, thereby limiting its use significantly. S7 PLC-SIM allows you to do online editing just as a real S7 PLC. My advice: get it.

I say that they are quite different.

STEP7 has a more rigid "feel", compared to RSLogix.

The STEP7 manuals can be a little confusing, as the translation from german makes for some strange instructions.

Siemens has just released a new version of STEP7 (v5.2) that should be much easier to use (they say). STEP7 lite (for S7-300) should allready have this easy-to-use makeover.

The most important differences are:

1. RSLogix is only LADDER,

STEP7 is STL (statement list), LAD and FBD (logic funtion blocks).

Notice: STL can not allways be converted to LAD or FBD.

2. RSLogix does not format variables into types.

STEP7 requires that variables define their type (word, int, real etc.)

It's a pain in the ... But on the other hand it will catch potential errors at edit-time.

3. RSLogix is quite "conventional" with regards to the program structure. STEP7 allows you to make reusable code via parameterizable subroutines. You will spend more time in the beginning, but it will pay back later.

4. RSLogix is great for doing math, especially with the COMPUTE instruction. STEP7 is just as capable, but is a LOT more rigid. You have to convert between INT's and DOUBLE's and REAL's as you go.

Count on 2-5 times as long time for programming math in STEP7 as compared to RSLogix.

5. RSLogix and STEP7 does online viewing of the program a little differently. RSLogix displays the variable content asyncronously to the program scan. STEP7 displays the variables strictly syncronously with the program scan. Good: It shows the data as they change instruction for instruction. Bad: If the rung or isntruction isn't executed, the data will not be displayed at all.

6. The STEP7 program simulator PLC-SIM is better (and cheaper) than AB's simulator. AB will not allow you to make online editing, thereby limiting its use significantly. S7 PLC-SIM allows you to do online editing just as a real S7 PLC. My advice: get it.

I've programmed both systems since 1986 (S5, later S7, PLC2,3,5,CLX). S7 has a complete different programming strategy than any AB PLC.

Usually, S7 programs are much shorter than AB, because you should use FC's. I agree, it's a pain if you do not have your own FC library, once you have it, programming is like 25-50% faster than AB. Also it gives you the ability, to upgrade a single part of your program (and as long, as you don't have to mess with the FC interface, you can upgrade only without interupting the process!)

S7 does not require additional tools like RSNetworks; all IO configuration is edited and kept in the project (and is much easier than AB).

S7 offers a wide range of scalable performace (dependig on what series and CPU you use.) In general, a S7-416 ist about 3-7 times faster than a CLX 5555! If you need performance, S7 is the better choice.

It's right: S7 is more like a RISC-Processor but it's in your (programmers) hand, to squeeze the best out of it.

It's right: Communication is a pain in the ... , but this does not apply to profibus DP - I/O connections. They are faster and easier then anything from AB.

S7 does very much support multiple people working on one project. You can centralize the project on one PC and access it from multiple stations simultaniously, Step7 will take care for the project consistance. (pretty good for commissioning!)

S7 also supports all kind of user defined data types (UDT), same as CLX.

S7 is more difficult to learn! Manuals are pretty bad (ok for referencing if you know what you do). Once you know, what you do, it is lightyears ahead of what AB can offer.

Usually, S7 programs are much shorter than AB, because you should use FC's. I agree, it's a pain if you do not have your own FC library, once you have it, programming is like 25-50% faster than AB. Also it gives you the ability, to upgrade a single part of your program (and as long, as you don't have to mess with the FC interface, you can upgrade only without interupting the process!)

S7 does not require additional tools like RSNetworks; all IO configuration is edited and kept in the project (and is much easier than AB).

S7 offers a wide range of scalable performace (dependig on what series and CPU you use.) In general, a S7-416 ist about 3-7 times faster than a CLX 5555! If you need performance, S7 is the better choice.

It's right: S7 is more like a RISC-Processor but it's in your (programmers) hand, to squeeze the best out of it.

It's right: Communication is a pain in the ... , but this does not apply to profibus DP - I/O connections. They are faster and easier then anything from AB.

S7 does very much support multiple people working on one project. You can centralize the project on one PC and access it from multiple stations simultaniously, Step7 will take care for the project consistance. (pretty good for commissioning!)

S7 also supports all kind of user defined data types (UDT), same as CLX.

S7 is more difficult to learn! Manuals are pretty bad (ok for referencing if you know what you do). Once you know, what you do, it is lightyears ahead of what AB can offer.

seppoalanen

Member

cypher63 said:Usually, S7 programs are much shorter than AB, because you should use FC's. I agree, it's a pain if you do not have your own FC library, once you have it, programming is like 25-50% faster than AB.

I'm not agree. With my experience, programming by S7 takes 2-3 times more than by ctrl.

This is the formula:

int c = sqr((float a)^2 + (sint b)^2)/10.0 + ..... Please show me how short it is by S7.

USER DEFINED STRUCTURES in CTRL

STRUCTURE VFD

DINT RefSpeed

DINT CurSpeed

INT CurPower

BOOL NoAlarm

MANU Manufacturer

ETC....

STRUCTURE MANU

STRING Name

STRING Telephone

STRING www

....

STRUCTURE Conveyor

INT Position

VFD Inverter

....

so for conveyor 50;

C50 is varible type Conveyor for Conveyor 50

and ABB is variable type MANU for ABB

C50.Inverter.Manufacturer.Name = ABB.Name

C50.Inverter.Manufacturer.www = ABB.www

CPT: C50.Inverter.RefSpeed = 5*50.0

I'm trying to tell about Object oriented programming.

By S7 it is not so easy than by CTRL -as shown- maybe impossible .

Last edited:

JRW

Member

Give me the complete formula- I will write it in SCL-

Very easy

Very easy

seppoalanen

Member

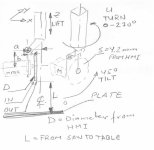

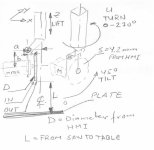

Circular saw solution. 4-axis in same controller, but 5'th tilting have on own controller. For linear interpolation, PLC's have to know where is saw blade in and out edges. There is plate on the table for sawing. X and Y makes linear interpolation when sawing, but starting coordinates must calculate by PLC.

I have done it by Omron CS1, but I know it is 100 times confortable by Allen Bradley CPT commands.

All units are mm/10 and angles are deg/10 for Servo-units and all calculations must done by float afcourse.

I have done it by Omron CS1, but I know it is 100 times confortable by Allen Bradley CPT commands.

All units are mm/10 and angles are deg/10 for Servo-units and all calculations must done by float afcourse.

Last edited:

JRW

Member

That drawing is great and everything- but where is this

complicated formula that can only be done in an Allen Bradley?

You started with

"int c = sqr((float a)^2 + (sint b)^2)/10.0 + ..."

Wheres the rest?

complicated formula that can only be done in an Allen Bradley?

You started with

"int c = sqr((float a)^2 + (sint b)^2)/10.0 + ..."

Wheres the rest?

kamenges

Member

JRW-

If you read the post from seppoalanen that has you curious he never states that a Siemens processor can't perform this function. He just says it takes more to enter it. You mention 'SCL'. Did you actually mean 'STL'? I've never heard about 'SCL'. If it is something different what is the cost adder for me to add it to my current copy of Step7 5.1 (assuming it brings something to the table for me)? I personally think that it is easier to enter an equation the way you write it out on paper than as it's discrete components in STL. I think that's the only point to take away from this.

cypher63-

You state that the S7-416 is 3-7 times faster than the CLX 5555. Just for my info is that a straight comparison of the same control application done on the two platforms or is it based on a comparison of clock speed or published boolean execution rates? If it is that much faster in real life I will definitely need to keep it in mind for some of my applications.

Jezz-

I'm sure you noticed that your request for a comparison between Step7 and Logix500 has mutated a bit to include Logix5000. I bounce back and forth between the AB Logix products and Step7 quite a bit. In general I think you will find the Logix stuff easier to get a handle on if you use it sparingly. If you use it every day Step7 has some really nice features, especially if you get used to STL. But you need to use it alot to stay sharp with it. If you do go the Step7 route it would be worth a class just to get your feet wet. There are enough differences in architecture that it isn't real easy to just straight-up go from Logix to Step7.

Keith

If you read the post from seppoalanen that has you curious he never states that a Siemens processor can't perform this function. He just says it takes more to enter it. You mention 'SCL'. Did you actually mean 'STL'? I've never heard about 'SCL'. If it is something different what is the cost adder for me to add it to my current copy of Step7 5.1 (assuming it brings something to the table for me)? I personally think that it is easier to enter an equation the way you write it out on paper than as it's discrete components in STL. I think that's the only point to take away from this.

cypher63-

You state that the S7-416 is 3-7 times faster than the CLX 5555. Just for my info is that a straight comparison of the same control application done on the two platforms or is it based on a comparison of clock speed or published boolean execution rates? If it is that much faster in real life I will definitely need to keep it in mind for some of my applications.

Jezz-

I'm sure you noticed that your request for a comparison between Step7 and Logix500 has mutated a bit to include Logix5000. I bounce back and forth between the AB Logix products and Step7 quite a bit. In general I think you will find the Logix stuff easier to get a handle on if you use it sparingly. If you use it every day Step7 has some really nice features, especially if you get used to STL. But you need to use it alot to stay sharp with it. If you do go the Step7 route it would be worth a class just to get your feet wet. There are enough differences in architecture that it isn't real easy to just straight-up go from Logix to Step7.

Keith

seppoalanen

Member

JRW

This is one of offsets for Z-coordinate (vertical) from tilting angle Beta something like this:

h=h0-cos(asn(a2/SQR(a2^2+(b1+D/2)^2))+Beta)*SQR(a2^2+(b1+D/2)^2)+b1+D/2

Where a2, b1 are content; D,h0 are from HMI;

Beta is calculated somewhere else for HMI

Also horzontal offset needed and x/y when turning, turning diameter debends of the tilting angle

etc.

With CS1 those offset countings takes more than 200 computing operations or variable type changes.

Please don't ask them all.

This is one of offsets for Z-coordinate (vertical) from tilting angle Beta something like this:

h=h0-cos(asn(a2/SQR(a2^2+(b1+D/2)^2))+Beta)*SQR(a2^2+(b1+D/2)^2)+b1+D/2

Where a2, b1 are content; D,h0 are from HMI;

Beta is calculated somewhere else for HMI

Also horzontal offset needed and x/y when turning, turning diameter debends of the tilting angle

etc.

With CS1 those offset countings takes more than 200 computing operations or variable type changes.

Please don't ask them all.

2 cents worth

We write for a verity of differnet PLC's. What we find is that the S7 stuff goes much faster than AB or GE or Modicon and so on for a lot of reasons but mainly because we don't have to re-invent code. Once we have a function we can use it over and over. Perhaps we are lacking experiance most of our work is SCADA talking to pump stations and irragation systems. We find communications with the S7 not any more trouble than with an AB. Clearly the Modicon or Control Microsystems stuff is simpler for communications. Something that never gets mentioned is the difference between "Structured" and "Linear" programming but I think most folks stash subroutines all over to quasi structure a linear program.

An example of what I mean would be a system that has a number of alarm lamps that need to blink for alarms that are not acknowledged and burn steady for acknowledged alarms that are not cleared. Add to that the need for a steady bit for active alarms regardless of ack to be sent to the remote SCADA master and a door switch input that turns the lamps off if the local panel door is closed.

This turns into perhaps 6 to 8 lines of ladder with an external pulse for the flash. With the S7 or S5 you write a function (or function block) that does the logic. Name all the input and output parameters and it becomes a box that you use over and over just by changeing the input and output operands. With the others you wind up cutting and pasting ladder until your blury eyed. Changing the inputs and outputs and perhaps taking extra time to debug your mistakes.

This is all just personel preferance, when you boil it all down because as a practial matter there ain't a lick of differance. We have to program what ever the client buys.

Lenny

We write for a verity of differnet PLC's. What we find is that the S7 stuff goes much faster than AB or GE or Modicon and so on for a lot of reasons but mainly because we don't have to re-invent code. Once we have a function we can use it over and over. Perhaps we are lacking experiance most of our work is SCADA talking to pump stations and irragation systems. We find communications with the S7 not any more trouble than with an AB. Clearly the Modicon or Control Microsystems stuff is simpler for communications. Something that never gets mentioned is the difference between "Structured" and "Linear" programming but I think most folks stash subroutines all over to quasi structure a linear program.

An example of what I mean would be a system that has a number of alarm lamps that need to blink for alarms that are not acknowledged and burn steady for acknowledged alarms that are not cleared. Add to that the need for a steady bit for active alarms regardless of ack to be sent to the remote SCADA master and a door switch input that turns the lamps off if the local panel door is closed.

This turns into perhaps 6 to 8 lines of ladder with an external pulse for the flash. With the S7 or S5 you write a function (or function block) that does the logic. Name all the input and output parameters and it becomes a box that you use over and over just by changeing the input and output operands. With the others you wind up cutting and pasting ladder until your blury eyed. Changing the inputs and outputs and perhaps taking extra time to debug your mistakes.

This is all just personel preferance, when you boil it all down because as a practial matter there ain't a lick of differance. We have to program what ever the client buys.

Lenny

Similar Topics

The past week we received a new piece of equipment from Germany which utilizes siemens controls. Typically in our company we use A.B. controls for...

- Replies

- 6

- Views

- 86

Hello

I have a s7-1200 and I would like to read the tags present in this controller with my controllogix controller. The two controllers don't use...

- Replies

- 5

- Views

- 121

Hi need help why this “failure 5 emergency stop “ appears at every startup in the morning ?

Have to shut off main switch at least 10 times on...

- Replies

- 19

- Views

- 286

i have two plc

1. s7-1212dc/dc/dc ip; 192.168.0.1

2. s7-1500 1513-1pn ip; 192.168.3.2

i need to get data from plc1 to plc2. any idea how to do...

- Replies

- 5

- Views

- 103

Hi everyone hope you'll well.

Is it possible for me to download a Crack version of tia portal v13..sorry to say this but the software is very...

- Replies

- 5

- Views

- 197