clone93

Member

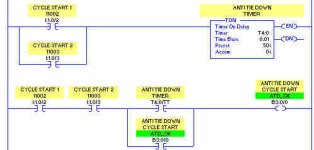

I'm writing my first "real" PLC program, and am trying to incorporate a 2-hand anti-tie down control on the machine. I am starting the machine cycle w/ 2 N.O. palm buttons. To make it an OSHA-legal anti-tie down, I need the buttons to be pressed almost simultaneously. I'm thinking there has to be a way to do that w/ a timer and/or a comparison function, where only 0.xx seconds can elapse between the 2, but haven't come up with the logistics of it yet.

Thanks in advance for your help!

Thanks in advance for your help!