hi everyone

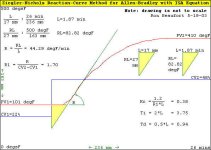

I tried ziegler nichols method to find the ultimate gain and period while system is oscillating. but I was not able to have perfect oscillations. the 2nd oscillations max value was always lower than the 1st one. this was a simple heating machanism. I took the open loop response with the controller output %10 it took more than 6 minutes to reach the system to temperatue 160 C from 40. I calculated the time constant for the system it was about 5.5 minutes. For the dead time I am not that sure. I was not able to find the paramters using open loop response of zeiler nichols. but I think there was stg wrong with the calculation of dead time. do you know some other method to find the parameters using open loop response.

by intution I tried some PID parameters but by changing the setpoint sometimes system made large overshoots although I gave the setpoint with a ramp. ýthink because of the bias term.

instead of giving setpoint with ramp I am planning to use the Kp only and when the temperature is close the set point I will include TI term. Do you think it works?

when I was reading the Q&A's I remember someone was offering to use a table for bias term. I really wonder the details. If I use the bias from a table don't I need an integral term? how can I determine the bias. I believe open loop response of the system will give an idea.

regards

I tried ziegler nichols method to find the ultimate gain and period while system is oscillating. but I was not able to have perfect oscillations. the 2nd oscillations max value was always lower than the 1st one. this was a simple heating machanism. I took the open loop response with the controller output %10 it took more than 6 minutes to reach the system to temperatue 160 C from 40. I calculated the time constant for the system it was about 5.5 minutes. For the dead time I am not that sure. I was not able to find the paramters using open loop response of zeiler nichols. but I think there was stg wrong with the calculation of dead time. do you know some other method to find the parameters using open loop response.

by intution I tried some PID parameters but by changing the setpoint sometimes system made large overshoots although I gave the setpoint with a ramp. ýthink because of the bias term.

instead of giving setpoint with ramp I am planning to use the Kp only and when the temperature is close the set point I will include TI term. Do you think it works?

when I was reading the Q&A's I remember someone was offering to use a table for bias term. I really wonder the details. If I use the bias from a table don't I need an integral term? how can I determine the bias. I believe open loop response of the system will give an idea.

regards