Nhrafan26

Member

Ok, I am trying to learn PLC programming and have a PLC already with a copy of WinGPC that I'm playing around with.

I have read through material on this site a few others here and there.

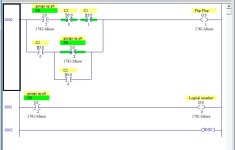

I was able to connect a circuit and write a simple little program to take input from a switch then activate 4 outputs after a timer of 200ms, then turn off each light sequentially at 8 sec, 6sec, 2sec then the last one.

I'm trying to think of things to write a program for and thought of the garage door opener.

I'm kind of stuck on the light circuit though...

How would you write a program to turn on the light when the door opens or closes then stay on for a period of inactivity until automatically turning off?

This sounded like a simple thing until I go to write it...

Thanks.

I have read through material on this site a few others here and there.

I was able to connect a circuit and write a simple little program to take input from a switch then activate 4 outputs after a timer of 200ms, then turn off each light sequentially at 8 sec, 6sec, 2sec then the last one.

I'm trying to think of things to write a program for and thought of the garage door opener.

I'm kind of stuck on the light circuit though...

How would you write a program to turn on the light when the door opens or closes then stay on for a period of inactivity until automatically turning off?

This sounded like a simple thing until I go to write it...

Thanks.