dale1627

Member

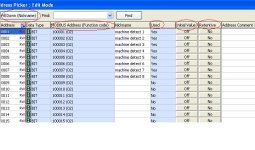

Has anyone tried out the AD Click yet? I've downloaded the software(free) and looked around in it. I like the math instruction alot more than the DirectSoft math functions. It also seems that you can store comments and nicknames in the PLC memory. Hopefully they will come out with new modules such as ethernet and analog, all they currently have are digital IO modules.

Dale

Dale