Here's the situation, we have a machine the fill containers. No big deal. I don't think they ever run in faster than 175 CPM, normally around 145ish. The problem is, the read out of the CPM data isn't very accurate. It will fluctuate I think a good 10 CPM.

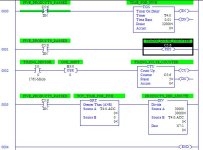

I tried doubling C5:6 from 5 to 10 and halving the rate from 12 to 6.

That seemed to make things worse. I realize now, I believe that I also need to change the Rate Timer T4:0 to double the time, since I doubled the counter (C5:6).

Before I trial and error this, does anyone know if this will improve anything? Or maybe you know a better way to go about it?

I didn't write this program, this is what came with the machine. Like usual, I just edit and change things.

Thanks in advance, I'll be checking in from time to time throughout the day.

I tried doubling C5:6 from 5 to 10 and halving the rate from 12 to 6.

That seemed to make things worse. I realize now, I believe that I also need to change the Rate Timer T4:0 to double the time, since I doubled the counter (C5:6).

Before I trial and error this, does anyone know if this will improve anything? Or maybe you know a better way to go about it?

I didn't write this program, this is what came with the machine. Like usual, I just edit and change things.

Thanks in advance, I'll be checking in from time to time throughout the day.