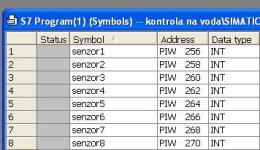

Hi. I need to read analog input from NH3 sensor !! The output is 0-24 mV,and te range of sensor is 0-14 mg/l I need to do this with step7 v5.4,and it MUST be with LADDER logic !!! After that,i need to display the results in wincc panel ! I just need to program this,its a faculty project ! I do not need to simulate step7 and wincc,i just need panel to simulate numbers between 0 - 14 mg/l . Have anybody idea how to do this with Ladder logic in step7 v.5.4 sp1 and wincc flexible 2007 !! Thanks !!

Analog inout?

- Thread starter ilija28

- Start date

Similar Topics

Hi, I have questions. I have Analog Input that need to put into Ignition Designer. But I don't know how to put?

Omron AD081-V1 Analog Input Card

Offset & Gain Adjustment

Entering Adjustment Mode

1. Set the input card in adjustment mode (Turn ON Dip SW No-1)...

Why AMIo800 Analog input module's I/O LED is Lighting up Red?

Checked module connections, 4-20ma wires etc but this light is continuously Lighting...

Hello! Hope you are great. I need to make a change in a PLC with ladder logic. I will mount a analog valve and I need to control it in ramp up...

Does anyone have experience wiring this type of analog pressure transmitter up? It's 4 wires. 3 blacks and 1 green which I assume is earth...