Hello All,

i'm a total newb to PLC programming so any help is appreciated.

I have an encoder mounted to a motor shaft. the encoder is used to measure the distance traveled of an arm that is being pulled by the motor.

the arm has to move 24", then 2", then 4", then 2", then 4", then repeat...

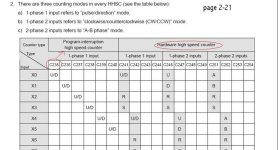

the original programmer wrote the program using software counters of the Delta SS PLC. it became apparent that the software counters weren't accurate enough for our application. i rewrote the 24" sequence of the program to utilize the built in high speed counter of the PLC. this solved the problem.

So here's my question...

I need to rewrite the program to utilize the high speed counter for each sequence. any suggestions on how i can accomplish this?

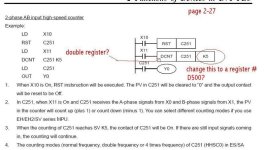

i assumed i could write some sort of logic that would change the preset value of the HSC after each successful sequence but i'm not quite sure how to do that.

i'm open to ideas! Thank you!

i'm a total newb to PLC programming so any help is appreciated.

I have an encoder mounted to a motor shaft. the encoder is used to measure the distance traveled of an arm that is being pulled by the motor.

the arm has to move 24", then 2", then 4", then 2", then 4", then repeat...

the original programmer wrote the program using software counters of the Delta SS PLC. it became apparent that the software counters weren't accurate enough for our application. i rewrote the 24" sequence of the program to utilize the built in high speed counter of the PLC. this solved the problem.

So here's my question...

I need to rewrite the program to utilize the high speed counter for each sequence. any suggestions on how i can accomplish this?

i assumed i could write some sort of logic that would change the preset value of the HSC after each successful sequence but i'm not quite sure how to do that.

i'm open to ideas! Thank you!