tomwhite007_2008

Member

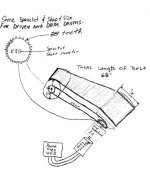

Gear Reduction Box = 3.0

Drive Sprocket = 22 Teeth

Driven Sprocket = 88 Teeth

VFD = PowerFlex 40

I have a VFD controlling the speed of a conveyor. I am sending it a frequency from 0 to 60HZ. The customer wants to know the speed of the conveyor in Feet/Minute. So I have a Motor driving a Gearbox. The Gearbox drives the Drive Sprocket. On this Sprocket there is a chain that drives the Driven Sprocket. How do calculate Ft\min the conveyor is moving if I know the frequency? Thanks for your response.

Drive Sprocket = 22 Teeth

Driven Sprocket = 88 Teeth

VFD = PowerFlex 40

I have a VFD controlling the speed of a conveyor. I am sending it a frequency from 0 to 60HZ. The customer wants to know the speed of the conveyor in Feet/Minute. So I have a Motor driving a Gearbox. The Gearbox drives the Drive Sprocket. On this Sprocket there is a chain that drives the Driven Sprocket. How do calculate Ft\min the conveyor is moving if I know the frequency? Thanks for your response.