indubasu

Member

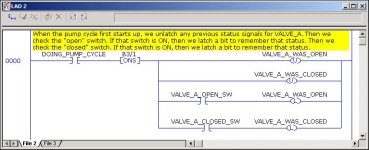

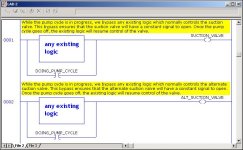

1. I need to start a pump by turning on a bit from the HMI (i.e. issue an HMI command) and keep it running for 3 hrs and then unlatch this bit after 3 hrs.

2. Before this pump starts to run I need to ensure that a couple of valves are open in order for the pump to run.

3. Before issuing the HMI command for the pump to start running, the two valves called suction valve and alternate suction valve can be in any position i.e. both open or both close or one open and the other close.

4. I need to open both the valves and get the pump to start.

5. After the 3 hr timer times out pump should stop running and the valves should go back to their original states (states that they were in before the HMI command was issued)

6. I have the pump turn on command logic figured out but am having difficulty with regards to maintaining the original states of the two valves after the timer times out. How do I get them to revert back to the states they were in before the pump turn on HMI command was issued?

Any takers?

2. Before this pump starts to run I need to ensure that a couple of valves are open in order for the pump to run.

3. Before issuing the HMI command for the pump to start running, the two valves called suction valve and alternate suction valve can be in any position i.e. both open or both close or one open and the other close.

4. I need to open both the valves and get the pump to start.

5. After the 3 hr timer times out pump should stop running and the valves should go back to their original states (states that they were in before the HMI command was issued)

6. I have the pump turn on command logic figured out but am having difficulty with regards to maintaining the original states of the two valves after the timer times out. How do I get them to revert back to the states they were in before the pump turn on HMI command was issued?

Any takers?