Mike Lewallen

Member

I am looking for some help developing PID loops in a PLC

The PLC is TI505 family. I have Tisoft & Workshop. I've created simple heating loops in the PLC many times, but I have no idea how to attach the following problem.

I have been challenged to fill a tank with 2 ingredients (1 solid and 1 liquid)

System layout: A solid is screw feed into the end of the horizonal mixer. A liquid is pumped into the same end of the horizonal mixer. The mixture then falls out (gravity) the other end of the mixer into a holding tank. The screw (solid) is on a Siemens MM440 drive and the pump (liquid) is also on a MM440 drive. Both the screw and the pump outputs are the equation of a straigt line (they are linear). The holding tank is on load cells so I alway know the level.

I want to accomplish 2 things.

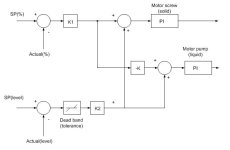

1) I know I must add 65% solid and 35% liquid. I want to use a PID loop to feed both the liquid and solid into the holding tank (thru the mixer). The "fuller" the tank the slower the addition. The "emptier" the holding tank the faster the screw and pump will run. I'm trying to make long batches.

2) The holding tank has a circulation loop with a nuclear density guage. So I always have a density solid vs liquid feedback. I know I want to maintain 65% solid and figured I would use a PID loop to bump the speed of the pump up or down to maintain the 65% solid.

So 2 things would influence the speed of the pump (1 being level of the holding tank and the other the feedback from the density guage).

Should I use a PID loop and somehow apply it to the curve (straight line) of both the pump and the screw?

Any help would be appreciated. Sorry for the bad spelling!

The PLC is TI505 family. I have Tisoft & Workshop. I've created simple heating loops in the PLC many times, but I have no idea how to attach the following problem.

I have been challenged to fill a tank with 2 ingredients (1 solid and 1 liquid)

System layout: A solid is screw feed into the end of the horizonal mixer. A liquid is pumped into the same end of the horizonal mixer. The mixture then falls out (gravity) the other end of the mixer into a holding tank. The screw (solid) is on a Siemens MM440 drive and the pump (liquid) is also on a MM440 drive. Both the screw and the pump outputs are the equation of a straigt line (they are linear). The holding tank is on load cells so I alway know the level.

I want to accomplish 2 things.

1) I know I must add 65% solid and 35% liquid. I want to use a PID loop to feed both the liquid and solid into the holding tank (thru the mixer). The "fuller" the tank the slower the addition. The "emptier" the holding tank the faster the screw and pump will run. I'm trying to make long batches.

2) The holding tank has a circulation loop with a nuclear density guage. So I always have a density solid vs liquid feedback. I know I want to maintain 65% solid and figured I would use a PID loop to bump the speed of the pump up or down to maintain the 65% solid.

So 2 things would influence the speed of the pump (1 being level of the holding tank and the other the feedback from the density guage).

Should I use a PID loop and somehow apply it to the curve (straight line) of both the pump and the screw?

Any help would be appreciated. Sorry for the bad spelling!