Hi

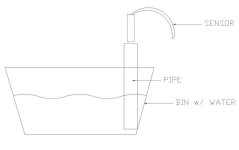

Have anyone tried using an ultrasonic sensor (for detecting the water height) in a material bathing/ cleaning bin (with deionized water & soap) that uses ultrasonic wave, creating fine forces on the water (solution), therefore, eliminating stain on the material?

My concern is that there may be interference cause by using an ultrasonic sensor to a solution bath that uses ultrasonic wave as well..

If my desccription wasn't clear, kindly comment..I will try to expand it as possible..

Best regards,

theripley

Have anyone tried using an ultrasonic sensor (for detecting the water height) in a material bathing/ cleaning bin (with deionized water & soap) that uses ultrasonic wave, creating fine forces on the water (solution), therefore, eliminating stain on the material?

My concern is that there may be interference cause by using an ultrasonic sensor to a solution bath that uses ultrasonic wave as well..

If my desccription wasn't clear, kindly comment..I will try to expand it as possible..

Best regards,

theripley