Christoff84

Lifetime Supporting Member + Moderator

I've looked through the posts on this topic and seen some pretty good ideas on how to do this. I've written a routine to track pallets along a conveyor that I think will work, but I'd like some input on it.

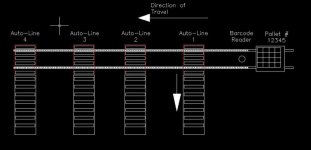

Our basic system is a barcode scanner at the beginning of the conveyor with 4 90 degree transfers along the length. Each transfer is about 10 feet apart, with the pallets being 1 foot square.

The pluses I can see from a system like this is that if a pallet is taken off or added to the conveyor it really shouldn't matter as the positions will never be right when it makes a sensor at a transfer.

The negatives I can see are my use of jump instructions. I don't think this routine would scale well to a larger stack as the watchdog timer and address space would be an issue.

If anyone has any tips or thoughts on the program, please share them. This is my first time attempting a tracking system and my first attempt at indexed addressing.

Our basic system is a barcode scanner at the beginning of the conveyor with 4 90 degree transfers along the length. Each transfer is about 10 feet apart, with the pallets being 1 foot square.

The pluses I can see from a system like this is that if a pallet is taken off or added to the conveyor it really shouldn't matter as the positions will never be right when it makes a sensor at a transfer.

The negatives I can see are my use of jump instructions. I don't think this routine would scale well to a larger stack as the watchdog timer and address space would be an issue.

If anyone has any tips or thoughts on the program, please share them. This is my first time attempting a tracking system and my first attempt at indexed addressing.