irondesk40

Member

have a question that i hope someone can assist with.

have a application that has a slc505 in it.

in the operator screen the operator selects to run fabric from 0-30 yard per minute. The machine was designed so that the operator always entered a value of 1,2,3,4,5 etc. all the way to 30.

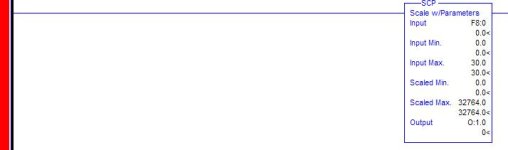

In the program there is a scp instructions that is taking what the operator enters and gives a output of 0- 32764 (0-10v) that is the value going to a inverter.

Not sure how to change it so that if the operator was to enter for example 5.5 yards per minute, or 5.75 yards per minute it could be scaled to give the proper value from 0-32764 (0-10v) to the inverter.

Can you do scp in the slc505 and use floating point values?

confused.

thanks

have a application that has a slc505 in it.

in the operator screen the operator selects to run fabric from 0-30 yard per minute. The machine was designed so that the operator always entered a value of 1,2,3,4,5 etc. all the way to 30.

In the program there is a scp instructions that is taking what the operator enters and gives a output of 0- 32764 (0-10v) that is the value going to a inverter.

Not sure how to change it so that if the operator was to enter for example 5.5 yards per minute, or 5.75 yards per minute it could be scaled to give the proper value from 0-32764 (0-10v) to the inverter.

Can you do scp in the slc505 and use floating point values?

confused.

thanks