You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ladder Logic: Scale with parameters

- Thread starter Zephyr

- Start date

Mickey

Lifetime Supporting Member

Mickey

Lifetime Supporting Member

I was afraid of that. No big deal, production wants a limitation on the speed of the machine, of course, while they are running!

Thanks for the input.

What processor do you have? Some support online editing.

Mickey, your example code will not clamp the output corresponding to max input, it simply stops executing the SCP when the input value is outside the Min/Max Input Range.

If the input value step-changed from 4000 to 5001, the output would not go to 65.

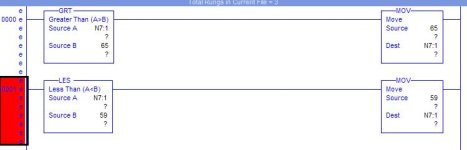

It would be better to clamp the output of the SCP with two rungs

GRT N7:1 65 MOV 65 N7:1

LES N7:1 59 MOV 59 N7:1

If the input value step-changed from 4000 to 5001, the output would not go to 65.

It would be better to clamp the output of the SCP with two rungs

GRT N7:1 65 MOV 65 N7:1

LES N7:1 59 MOV 59 N7:1

Mickey

Lifetime Supporting Member

Mickey, your example code will not clamp the output corresponding to max input, it simply stops executing the SCP when the input value is outside the Min/Max Input Range.

If the input value step-changed from 4000 to 5001, the output would not go to 65.

It would be better to clamp the output of the SCP with two rungs

GRT N7:1 65 MOV 65 N7:1

LES N7:1 59 MOV 59 N7:1

Your right of-course.

The code I posted says if the operator enters an invalid value

( outside the limits) the corresponding out will not change.

This forces the operator to enter a valid value ( within limits).

Nothing wrong with your example though. But it does allow the operator to enter invalid values.

bernie_carlton

Lifetime Supporting Member + Moderator

Is it possible to implement the limits on the operator in the display program numeric input object?

Mickey

Lifetime Supporting Member

Is it possible to implement the limits on the operator in the display program numeric input object?

Do it both places. (PLC and HMI/SCADA) On SCADA systems I have even programmed a pop-up message telling them they screwed up.

( "Invalid Data Enter")

valski gonzaga

Member

Hi,I have a proximity sensor that will count the speed/rpm of a machine. can this be possible to use a digital input module (siemens plc s7300)and have it program to read the rpm/speed on the tp170HMI? any example please? thanks

Mickey, your example code will not clamp the output corresponding to max input, it simply stops executing the SCP when the input value is outside the Min/Max Input Range.

If the input value step-changed from 4000 to 5001, the output would not go to 65.

It would be better to clamp the output of the SCP with two rungs

GRT N7:1 65 MOV 65 N7:1

LES N7:1 59 MOV 59 N7:1

Please give an example of how to execute in the rungs. Thanks

Mickey

Lifetime Supporting Member

Mickey

Lifetime Supporting Member

So I could use the GRT and LES rather than the LIM, or, in conjunction with it? Thanks for your help.

Your choice. You really don't need both though.

IMO, I prefer the limit because it stops the operator from entering an invalid number.

With the GRT,LES method the operator can still enter an invalid number although it will be clamped.

Since operators are unaware that attempting to make the speed faster than 65 will take the speed to 0 (They'll freak out and start pushing any button that blinks) then I should probably use the GRT and LES functions. You guys are great. Thanks a bunch.

Mickey

Lifetime Supporting Member

Since operators are unaware that attempting to make the speed faster than 65 will take the speed to 0 (They'll freak out and start pushing any button that blinks) then I should probably use the GRT and LES functions. You guys are great. Thanks a bunch.

The use of the limit instruction I posted will not move the speed to zero if the number is out of range. It will do nothing. As the rung will be false, no change will occur it will just stay put at whatever value is there.

But do whatever you are comfortable with.

Similar Topics

I have a machine which is undergoing upgradation. As part of the process two SEW drives are being replaced., existing Gen B with new Gen C. The...

- Replies

- 3

- Views

- 192

Good morning crew!

Ok my logic works but I am missing something. When the start button is pushed it should like the red light for 4sec then shut...

- Replies

- 13

- Views

- 416

Working on project will update after it is completed.

- Replies

- 2

- Views

- 352

Can someone help me piece this problem together. I have a lot of it down I think but cannot seem to get it right. Probably an easy one for most on...

- Replies

- 1

- Views

- 301

Hi everyone,

I'm working on a project that involves using a Keyence LR-X100 sensor in Studio 5000 V35 ladder logic to determine the object's...

- Replies

- 4

- Views

- 674