Doug W

Member

Greetings,

PLC: SLC 5/04

DCS: DeltaV ver 9.3

Originally at our plant, the diffential pressure across our baghouse came from a single Rosemount differential pressure transmitter as I:25.0.

That differential pressure came into the PLC and was sent to the DCS throught an SCP block as O:28.0.

It was decided to change the differential pressure transmitter to 2 pressure transmitters and subtract the difference in the PLC, then send it to the DCS.

Someone did the change for us and did not change I:25.0 as the input for the SCP block. So I was trying to fix things.

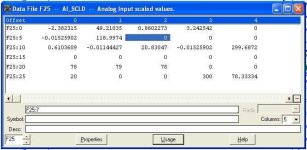

Here are some screenshots of what I am trying to do and what I have explained above.

http://webpages.charter.net/drw46/examples/5_Hamon_PLC-b.jpg

Question 1. Can I accomplish what I want to do as an online edit?

Question 2. Is what I am doing essentially correct?

I am in the position of being a PLC novice but knowing more than anyone else in the plant so by default I am the expert.

Thanks for any help,

Doug

PLC: SLC 5/04

DCS: DeltaV ver 9.3

Originally at our plant, the diffential pressure across our baghouse came from a single Rosemount differential pressure transmitter as I:25.0.

That differential pressure came into the PLC and was sent to the DCS throught an SCP block as O:28.0.

It was decided to change the differential pressure transmitter to 2 pressure transmitters and subtract the difference in the PLC, then send it to the DCS.

Someone did the change for us and did not change I:25.0 as the input for the SCP block. So I was trying to fix things.

Here are some screenshots of what I am trying to do and what I have explained above.

http://webpages.charter.net/drw46/examples/5_Hamon_PLC-b.jpg

Question 1. Can I accomplish what I want to do as an online edit?

Question 2. Is what I am doing essentially correct?

I am in the position of being a PLC novice but knowing more than anyone else in the plant so by default I am the expert.

Thanks for any help,

Doug