geniusintraining

Lifetime Supporting Member + Moderator

Hello everyone,

I have a customer that needs help with V Memory and I am not am not very good maybe someone here can help...

We have gone through the manual but its still not very clear

I suggested the manual appx F (see attached if needed)

I am also at a loss... can anyone explain it better then the manual? is there a better place in the manual the has a program showing a MOV... or are we making this more then it should be?

Thank you

Mark

I have a customer that needs help with V Memory and I am not am not very good maybe someone here can help...

We have gone through the manual but its still not very clear

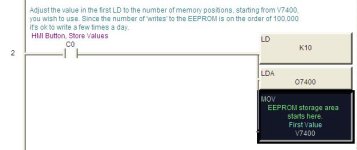

FROM MY Customer.... I use the C-more touch panel to control the DL05. I want to write a ladder program for a control. The program will include 10 timer functions which the operator will have to enter 10 timer values then store them in the non-volatile memory. These values would not be change often but will be once a while. I do not have the option of using the option slot because I placed an analog input module. According to the manual, I may use the EEPROM V-memory but I don't know how.

I suggested the manual appx F (see attached if needed)

From my customer.... I think the RAM V7400 is different from the ROM V7400 (page F-3). For this reason, the book suggests to use the MOV instruction in the ladder to move the data from the RAM V7400, for example, to the ROM V7400. I'm not sure I understand it correctly. But I don't know how to write to move to the ROM as the operator enter value on the C-more panel.

I am also at a loss... can anyone explain it better then the manual? is there a better place in the manual the has a program showing a MOV... or are we making this more then it should be?

Thank you

Mark