mavilleda

Member

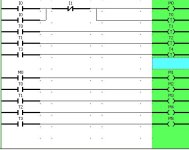

I'd been assign to work in my first PLC program, There are six big Fans that I have to turn ON the first FAN, then 5 second late the second one and so on. I have to use only one push botton to turn ON and another push botton to turn then OFF.

Input voltage for the fanthe system is 460V, I have to use a micrologix PLC.

Would you please help me out to complete this project, I have to summit a preliminar PLC program and controls drawing this coming tuesday October 7.

Input voltage for the fanthe system is 460V, I have to use a micrologix PLC.

Would you please help me out to complete this project, I have to summit a preliminar PLC program and controls drawing this coming tuesday October 7.