You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

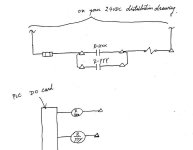

Wire two output channels to one solenoid

- Thread starter elmatador

- Start date

harryting

Lifetime Supporting Member

I don't think that's a good way of doing thing... why not use PLC logic? What's your intend action for one on, both on, etc..?

Last edited:

milldrone

Member

Hi Guys,

Is there a way where you can wire two discrete output channels to a single solenoid?

I can think of several reasons to do this ranging from "I'm bored, let's do something" to "I have two PLC's and I need them to both turn on the same field device". The reasons you want to do this determine how.

I can think of several reasons to do this ranging from "I'm bored, let's do something" to "I have two PLC's and I need them to both turn on the same field device". The reasons you want to do this determine how.

We have this whole new SIL-2 system. They want to have redundancy for the control to the ESD valves. So we need to wire a single solenoid to two seperate output channels

Christoff84

Lifetime Supporting Member + Moderator

It depends if both PLCs use the same power source or not. If they do, just put the 2 wires together (generally a diode would be a good idea to have on both lines). If not, you'll have to figure out something with relays connected in parallel to the solenoid coil.

When your dealing with safety, why not use 2 valves as stated above?

When your dealing with safety, why not use 2 valves as stated above?

I have been trying to explain it to the guys to use two valves. This would be a much better method.

I have noticed in SIL-3 systems where they have three pressure transmitters on the line.

We have around 20 esd valves on this site. I am not sure if the process company is just trying to cheap out. they are keeping me in the dark

I have noticed in SIL-3 systems where they have three pressure transmitters on the line.

We have around 20 esd valves on this site. I am not sure if the process company is just trying to cheap out. they are keeping me in the dark

harryting

Lifetime Supporting Member

Maybe someone who does safety circuit can enlighten me. Isn't a safety relay typically used in such situation?

OP said it's for a ESD (emergency shutdown valve), so the output from PLC is Normally energized and the ESD shuts when EITHER signal is lost. Correct?

OP said it's for a ESD (emergency shutdown valve), so the output from PLC is Normally energized and the ESD shuts when EITHER signal is lost. Correct?

sthompson

Lifetime Supporting Member + Moderator

I would not connect two outputs together, that is a good way to damage them if they are fighting each other. Your options depend on what you want to do. Is it an either or situation, or do both outputs need to be on to allow the Solenoid to engage? What if one PLC says solenoid off, and the other PLC says solenoid on? What needs to happen then?

It is certainly a solvable problem, but you have to set out your exact parameters first.

Stu.....

It is certainly a solvable problem, but you have to set out your exact parameters first.

Stu.....

Maybe someone who does safety circuit can enlighten me. Isn't a safety relay typically used in such situation?

OP said it's for a ESD (emergency shutdown valve), so the output from PLC is Normally energized and the ESD shuts when EITHER signal is lost. Correct?

normally these ESD valves close on a hard ESD pushbutton, fire, or hi hi h2s/lel. In such a situation we normally drop the power to the output cards. So the ESD valves would loose power and would return to their fail-safe position which is FAIL CLOSED. This would also apply to blowdown valves which would just go Fail Open on loss of power

BudW

Member

Long ago this configuration was the standard for places like Chrysler. Two (dual) outputs for each solenoid. One output from the high side of the line voltage or + for DC was placed on one side of the solenoid and a output from the low side of the line voltage or – (return) for DC was used on the other side of the solenoid. This was done just in case one of the output (relay) contacts were to weld together (stick together). If this happened and the solenoid was connected to only one output of course the solenoid would not de-energize (turn off). Now that the outputs have been changed from relay contacts to triac/SCR (electronic) with on/off feedback you do not see the dual output for solenoids as much.

Hope this helps

Bud

Hope this helps

Bud

I would not connect two outputs together, that is a good way to damage them if they are fighting each other. Your options depend on what you want to do. Is it an either or situation, or do both outputs need to be on to allow the Solenoid to engage? What if one PLC says solenoid off, and the other PLC says solenoid on? What needs to happen then?

It is certainly a solvable problem, but you have to set out your exact parameters first.

Stu.....

well as far as i know it will have to be an either or situation. We will most likely have it timed in such a way where one output will try an open that valve. Once a certain amount of time has passed and the open switch has not registered then we would attempt to fire the other output to open the valve. If both commands dont register and OPEN status then we would ESD the Plant.

BudW

Member

Dual output to a solenoid, see attached PDF.

milldrone

Member

http://www.gminternationalsrl.com/?pid=D1047S

?

Edit: they have some sil3 stuff for NE loads here

http://www.gminternationalsrl.com/?pid=D1098S

?

Edit: they have some sil3 stuff for NE loads here

http://www.gminternationalsrl.com/?pid=D1098S

Last edited:

Similar Topics

Hi everyone, I need some help I new with omron plc. I using plc CP1L. When I do the program it's good and the plc is function as program. But when...

- Replies

- 1

- Views

- 83

I am using a siemens output module and I saw that there is also 4 wire diagram for voltage output.

Is there anyone who can explain the reason of...

- Replies

- 11

- Views

- 2,809

Good afternoon forum members.

We recently had a fuse blow on the wiring between a 1756-OF6CI analog out card and a control valve (which we have...

- Replies

- 2

- Views

- 2,653

We have a stamping press with some prox sensors on the die for slug detection and we just ran into a problem where the output from one of the...

- Replies

- 1

- Views

- 1,306

Do you use the PLC input or output address as the wire number or do you use the sheet-line number?

The system that I am currently working on is a...

- Replies

- 16

- Views

- 8,722