urvinder_pal

Member

Dear all,

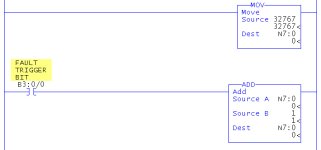

Is there an instruction or a code that can make the PLC go to a fault state after a certain time period and the fault can only be reset thro a laptop and only if online with the processor. This is important because somehow people have started ignoring the warnings.

thanks'

kanwar

Is there an instruction or a code that can make the PLC go to a fault state after a certain time period and the fault can only be reset thro a laptop and only if online with the processor. This is important because somehow people have started ignoring the warnings.

thanks'

kanwar